The 3D printing industry has come a long way from the handmade prototypes in the garage to the parts that are so precisely engineered that they are used in hospitals, factories, and even space missions. The main factor that has made this transition possible is materials.

The choice of the right material plays a crucial role in the characteristics of the printed part: it affects the strenght, the flexibility, the surface quality, and even the compatibility with living tissues. The arsenal of materials today is no longer limited to only basic plastics but rather goes up to medical-grade polymers like PEEK, industrial-type resins, powder-based nylons, and metals with superior characteristics.

This article will take the reader on a journey through different 3D printing materials by looking at all the major printing technologies and their impact on the medical, automotive, and engineering sectors.

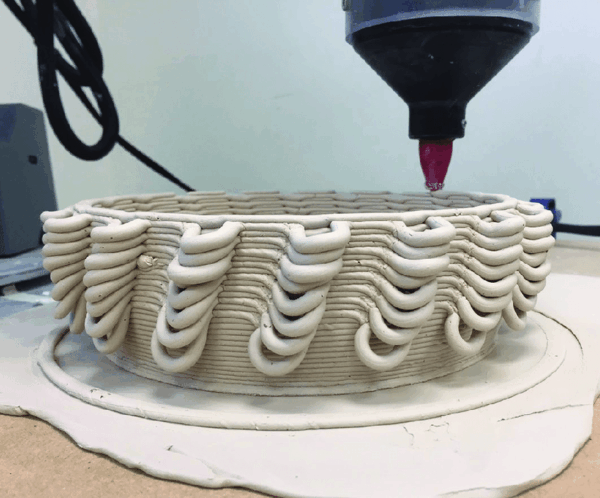

Fused Deposition Modeling (FDM) is still the most popular 3D printing technology because it’s the most accessible and reliable of all. It uses the process of melting thermoplastic filament and extruding it layer by layer to form an object.

The following are the main materials utilized in FDM:

-

PLA (Polylactic Acid) – It is the primary material for novices and schools. It’s inexpensive, simple to use, and compostable. PLA is perfect for working models, visual prototypes, and ornamental pieces.

-

ABS (Acrylonitrile Butadiene Styrene) – This material is famous for its strength and resistance to impact; therefore, it is used for parts of cars, covers, and prototypes of machines.

-

ASA (Acrylonitrile Styrene Acrylate) – This material is like ABS but is resistant to UV radiation, thus perfect for outdoor applications.

-

PETG (Polyethylene Terephthalate Glycol) – This material is a strong contender in the battle between flexibility and strength. PETG is accepted for its durability and chemical resistance in functional parts and fixtures, thus being the most popular material in the area of functional parts and fixtures.

Advanced FDM materials

-

TPU (Thermoplastic Polyurethane): A flexible filament that is very similar to rubber and it is well-known for its elasticity and resistance to impact. TPU is ideal for manufacturing parts like phone cases, gaskets, shoe soles, and applications in wearables. Its long life and ability to absorb vibrations are the factors making it popular in the sectors of automotive and consumer goods.

-

Filament Reinforced with Carbon Fibers: Usually, these filaments are composed of a polymer like nylon, PETG, or PLA along with carbon fibers. When carbon fibers are infused into the base polyes, it leads to the formation of an extremely stiff and light composite material which, besides being great in dimensional stability, also has a high tolerance to heat. Thus, the automotive and aerospace industries are using carbon fiber-reinforced materials to produce engineering prototypes, drone frames, parts of cars and planes where the ratio of strength to weight is crucial.

However, for engineers and medical professionals, standard thermoplastics sometimes fall short. That’s where PEEK comes in.

Check out FDM machines:

Bambu Lab

Ultimaker

Flashforge

PEEK: The High-Performance Polymer Redefining 3D Printing

Polyether Ether Ketone (PEEK) remains one of the most advanced thermoplastics used in additive manufacturing even now. It ranks at the top of the polymer performance hierarchy — able to withstand extreme temperatures, enormous pressures, and super corrosive settings.

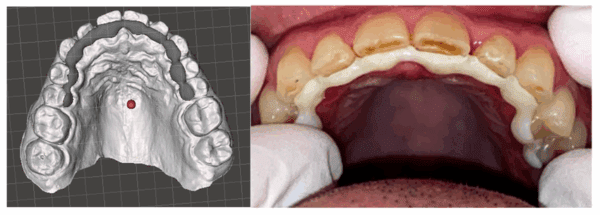

Medical Applications of PEEK

PEEK is biocompatible, light in weight, and radiolucent (it doesn’t obstruct X-ray or CT scan images). These characteristics render it suitable for:

-

Spinal implants and other orthopedic devices

-

Cranial plates and dental restorations

-

Surgical instruments and patient-specific implants

The ability of PEEK to imitate the mechanical properties of bone results in strong fusion and less strain on the human body when compared with titanium implants.

Engineering and Industrial Applications

In the case of high-stress environments, PEEK is able to take the place of metals and at the same time, neither strength nor performance is compromised.

-

Aerospace: In case of PEEK, the parts are used in jet engines, brackets, and insulation components which are pretty much inaccessible due to their heat and fuel resistance among other things.

-

Automotive: The use of PEEK parts in the very hot areas like the area under the hood helps maintain strength while simultaneously reducing the weight of the vehicle.

-

Oil and Gas: PEEK is very hard to get destroyed by harsh chemicals and pressure; thus it is just the right material for seals, valves, and connectors.

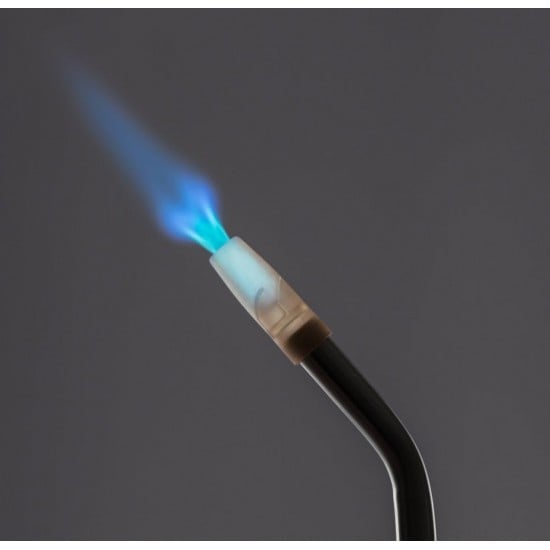

On the other hand, the difficult print parameters set by PEEK, which include high extrusion temperatures (up to 400°C) and a heated chamber, confine its application to 3D printers for industrial high-performance materials.

Check out machines that can use PEEK:

Intamsys

Resin Materials: Precision in Every Layer

Resin-based 3D printing, namely SLA (Stereolithography) and DLP (Digital Light Processing), employs photopolymers that are liquid and then illuminated to become solid. The end product is incredibly precise and detailed, which is impossible to achieve with most FDM prints.

The following are some of the common types of resin:

-

Standard Resin: It is perfect for the visual representations of products, models of arts, and designs of concepts.

-

Tough and Durable Resin: It is meant for parts whose performance requires to be both impact-resistant and flexible.

-

Flexible Resin: It has properties similar to rubber, and thus it is perfect for ergonomic models or grips.

-

High-Temperature Resin: It is used for molds and tooling that have to be heat-resistant.

-

Dental and Biocompatible Resin: It is used for dental crowns, surgical guides, and temporary implants.

-

Castable Resin: It is widely used in jewelry and manufacturing for the direct casting of intricate designs.

The quality of resin materials is so high that they are considered indispensable in the medical, dental, fashion, and prototyping industries. Surface quality and minute accuracy are the key requirements in these fields.

Check out these Resin Printer:

Phrozen

Formlabs

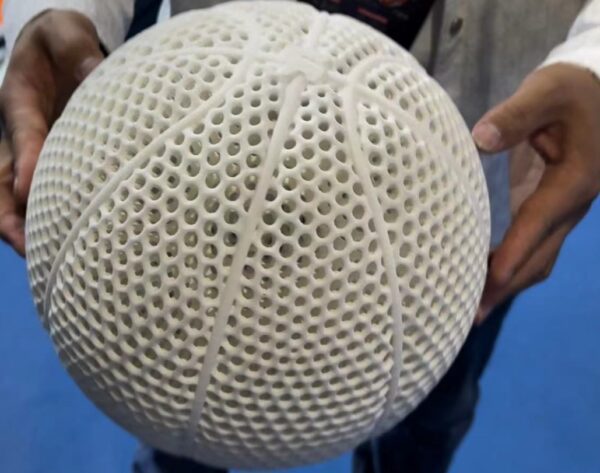

Powder-Based Materials: Industrial Strength from SLS and MJF

Powder-based 3D printing technologies like Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) are a major step toward industrial-grade manufacturing. Rather than the filaments or liquid resin these technologies have been using the very fine powdered materials that are joined together with the help of heat or laser energy.

Among the most commonly used cupping materials are:

-

Nylon (PA12, PA11): the characteristics of nylon are that they are all very good, that is, they are strong, flexible, and resistant to chemicals. These are the most widely used powders, which are suitable for functional prototypes, enclosures, and mechanical assemblies.

-

TPU (Thermoplastic Polyurethane): It brings up the qualities of rubber, allowing the material to be less brittle, thus giving it a wider application area in footwear, wearables, and gaskets.

-

Carbon-Filled Nylon: Being light but very strong, it is used in the production of mechanical parts that do not need to be heat treated.

Such materials can be very well combined with complex shapes and at the same time being very durable and even ready for production. Powder-based technologies are often used in aerospace, medical devices, and consumer product development.

Check out our SLS machines:

Sinterit

Metal 3D Printing: Engineering Without Limits

For industries that require the highest quality performance, metal additive manufacturing has taken a different path. Processes such as DMLS, SLM, and Binder Jetting let manufacturers create metal components with complex shapes that cannot be produced through traditional cutting techniques.

Regular Metal Materials:

-

Stainless Steel: Strong, resistant to rust, and suitable for processing and mechanical parts.

-

Titanium: Heavy in comparison but extremely strong. Applied in aerospace, auto, and medical implants.

-

Aluminum: Great heat conductor and light weight make it suitable for car and drone parts.

-

Inconel: A nickel-based superalloy that can bear very high temperatures, used in electric turbine and gas engine parts.

-

Cobalt-Chrome: Has biocompatibility and is very durable, therefore it is used in prosthetic and dental implants.

Metal 3D printing enables part consolidation, reduced material waste, and lightweight optimization, leading to major efficiency gains across industries.

Emerging and Specialized Materials

As 3D printing continues to advance, new hybrid and composite materials are being introduced every year.

-

Bio-based materials are gaining popularity for sustainable printing.

-

Ceramic powders are being explored for specialized applications in electronics and biomedicine.

These emerging materials continue to push the boundaries of what’s possible – from custom medical implants to rocket engine parts.

Check out our metal 3D printers:

Desktop Metal

Final Thoughts

3D printing has evolved beyond rapid prototyping and is now associated with production, performance, and precision. With the use of various materials such as biocompatible PEEK implants and metal aerospace components, the next generation of additive manufacturing is being driven by materials.

The understanding of each material’s strengths will enable the innovators to design smarter, print faster, and build stronger as more industries accept 3D printing.

sources:

-

“PEEK 3D printing: what is PEEK and what is it used for?” — Roboze Blog. roboze.com

-

“Applications of 3D-Printed PEEK via Fused Filament Fabrication” — in the journal MDPI. MDPI

-

“All You Need to Know About PEEK for 3D printing” — 3Dnatives. 3Dnatives

-

“Ultimate 3D Printing Materials Guide” — Simplify3D. simplify3d.com

-

“Complete Guide to TPU 3D Printing” — 3D MonoTech (TPU specific). 3D Monotech

-

“3D printing materials guide: filaments, resins & powders …” — Sinterit. sinterit.com