Ultimaker is proud to announce the release of its new PETG material, designed specifically for great results with Ultimaker 3D printers.

Why has Ultimaker introduced a PETG material?

Ultimaker is always analyzing and striving to understand the landscape of the 3D printing industry, and we noticed a great deal of traction for PETG materials. In the latest Ultimaker 3D Printing Sentiment Index, for example, we saw that PETG is one of the most used and requested 3D printing plastics.

With this in mind, we began testing various third-party PETG materials that our customers were using. We were not always satisfied with the results, finding that many PETG filaments did not print well – with final results stringing, warping, or being incompatible with PVA and Breakaway support materials – or reliably enough to suit the demands of our customers.

Ultimaker PETG, however, brings the best printing experience to Ultimaker users, seamlessly integrating with our platform to ensure optimal print results – helping you increase your chances of achieving first-time right results and making it happen.

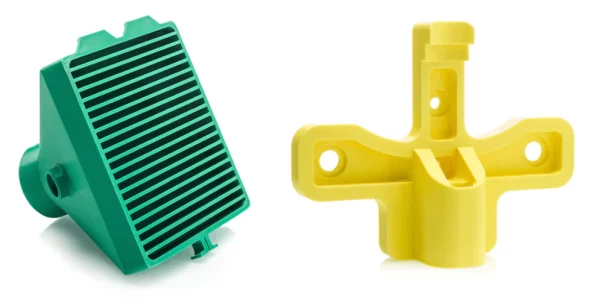

Ultimaker PETG properties make it ideal for functional prototypes and end-use parts

Why should you use Ultimaker PETG?

There are many benefits to printing with Ultimaker PETG. Among them:

- It’s for anyone – novice or expert. Ultimaker PETG is one of the easiest-to-use 3D printing materials on the market. With good adhesion and print profiles – including engineering intent profiles – anyone can quickly and easily start 3D printing with Ultimaker PETG

- It enables you to unlock the widest range of technical applications. Compared to PLA and Tough PLA, Ultimaker PETG unlocks the widest range of technical applications, offering the printability of PLA, but with the industrial properties you need. This enables you to create a wide range of industrial parts, tools, and prototypes. Ultimaker PETG offers the ideal balance of properties for Ultimaker users in industrial environments, with good all-around visual, functional, and mechanical properties that can withstand environmental influences such as wear, chemicals, and warmer temperatures

- It sets the standard for enterprise-grade, industrial use. Ultimaker PETG is one of the most affordable technical 3D printing materials. It is also perfectly suited for different industrial environments – versatile, safe, easy to print, and available in many colors. Together, this makes Ultimaker PETG easy to deploy across your organization – meaning fewer changeovers and increased standardization

How can you use Ultimaker PETG?

Ultimaker PETG is versatile, and can be used in the following ways:

- To create manufacturing aids your way. Ultimaker PETG is the perfect solution to creating custom manufacturing aids that ensure efficiency, order, and safety in an industrial environment. Available in a variety of colors – and with temperature, chemical, and wear-resistant properties – Ultimaker PETG enables you to create parts that you can use repeatedly, minimizing downtime so you can make it happen

- To create parts for industrial use. With chemical resistance against lubricants, oils, alcohol, acids, and bases – plus temperature resistance for warmer environments up to 76 °C – Ultimaker PETG is an excellent candidate for creating parts meant to work hard in a variety of industrial environments, such as waterproof sensor covers or color-coded manufacturing aids

- To create functional prototypes with the right properties, easily. Ultimaker PETG is a go-to material for creating functional prototypes ready for real-world testing. It features good printability, a balance between toughness and stiffness, plus chemical resistance, temperature resistance, and wear resistance, meaning you can design, create and iterate the prototype you need to get the job done

Choose from 14 colors, including transparent and fluorescent

What else does Ultimaker PETG offer?

Still not convinced? Take a look at more of the robust features Ultimaker PETG brings to the worktable.

- It’s part of the platform. With NFC detection and intent profiles, Ultimaker PETG integrates seamlessly with the Ultimaker platform, providing the best, most fluid 3D printing experience for Ultimaker users

- It’s for use across the spectrum. Available in multiple colors, including translucent and fluorescent, Ultimaker PETG is suited for a variety of use cases, from color-coding to transparent parts

- It’s a material workhorse. Ultimaker PETG features good toughness and is slightly bendable, meaning it is suitable for creating shatter-resistant functional parts that work, and work hard

- It’s meant for use – and reuse. Ultimaker PETG’s wear-resistant properties mean it is durable and not easily damaged by friction or use – meaning your parts will be built to last

- It’s ready for harsh environments. With chemical resistance against lubricants, oils, alcohol, acids, and bases, Ultimaker PETG creates parts, tools, and manufacturing aids suited to a variety of industrial environments

- It can take the heat. Able to withstand humid environments and temperatures up to 76 °C, Ultimaker PETG is a prime candidate for use in hardworking industrial environments

Commenting on the release of Ultimaker PETG, Miguel Calvo, CTO at Ultimaker said, “Adding Ultimaker PETG to our set of standard materials is a natural next step from the launch of our platform. It enhances our material portfolio as industrial use cases for 3D printing continue to rise. Its excellent all-round properties are a strong addition to our platform and ideal for typical industrial environments and applications. Ultimaker PETG will further fuel creativity and innovation as users work hard to ensure the continuation of production and everyday life, despite the external challenges we have all faced.”

Ready to find out more about how Ultimaker PETG can unlock the magic of the material so you can make it happen?

Contact us to get yours!

This guest post was originally written by David Durbin and was published on Ultimaker’s blog site. The content in this guest blog is for informational and educational purposes only and may contain copyrighted material from Ultimaker.

Source: Ultimaker