Bambu Lab Support for PA/PET 3D Printing Filament

Bambu Lab Support for PA/PET 3D Printing Filament

Product Features:

- Easy removal by hand

- Perfect support interface

- Recommended for PAHT-CF, PA6-CF, PET-CF, PA-GF, etc.

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use:

- ONLY used for support interface

- Not used for printing models alone

- Dry out before use

- Remove the support structure promptly

- AMS compatible

₱2,049.00

Bambu Lab Support for PA/PET 3D Printing Filament

Bambu Lab Support for PA/PET 3D Printing Filament

Product Features:

- Easy removal by hand

- Perfect support interface

- Recommended for PAHT-CF, PA6-CF, PET-CF, PA-GF, etc.

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use:

- ONLY used for support interface

- Not used for printing models alone

- Dry out before use

- Remove the support structure promptly

- AMS compatible

₱2,049.00

Bambu Lab Support for PA/PET 3D Printing Filament

-

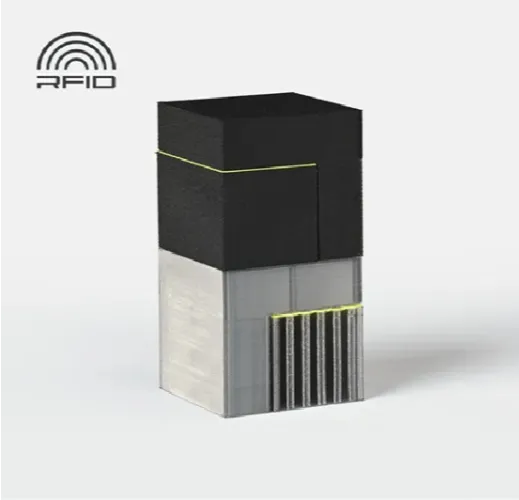

Purpose: Designed exclusively as a support interface material—not for printing models alone.

-

Compatibility: Recommended for use with high-temperature engineering filaments such as PAHT‑CF, PA6‑CF, PET‑CF, PA‑GF, etc.

-

Filament Specs:

-

Diameter: 1.75 mm ± 0.03 mm

-

Color: Green

-

Supplied on a high-temperature reusable spool

-

-

Printing Requirements:

-

Drying required: ~80 °C for 8–12 h (blast drying oven) or ~90 °C for 10 h on the heated bed

-

Maintain humidity below 20% RH, with desiccant

-

Nozzle temperature: 280–300 °C

-

Bed temperature (with glue): 80–110 °C

-

Print speed: Under 100 mm/s

-

AMS & RFID Integration:

-

Fully compatible with Bambu Lab’s Automatic Material System (AMS); parameters are embedded via RFID for automatic loading

-

Not compatible with AMS Lite

-

-

Handling Tips:

-

Remove supports within 2 hours after printing to avoid sticking from absorbed moisture

-

If parts become difficult to separate, re‑drying can help

-

-

Physical Characteristics:

-

Density: ~1.17 g/cm³

-

Melting temperature: ~255 °C

-

Melt flow index: ~29.2 ± 2.1 g/10 min

-