Ultimaker PP

Ultimaker PP (polypropylene) is durable. It has high toughness, exceptional fatigue resistance, and low friction. It also has good chemical, temperature, and electrical resistance. PP is one of the most widely used plastics on the planet. From electrical components to living hinges, PP is the go-to material for prototyping and end-use products.

Ultimaker PP

Ultimaker PP (polypropylene) is durable. It has high toughness, exceptional fatigue resistance, and low friction. It also has good chemical, temperature, and electrical resistance. PP is one of the most widely used plastics on the planet. From electrical components to living hinges, PP is the go-to material for prototyping and end-use products.

Ultimaker PP (polypropylene) is durable. It has high toughness, exceptional fatigue resistance, and low friction. It also has good chemical, temperature, and electrical resistance. PP is one of the most widely used plastics on the planet. From electrical components to living hinges, PP is the go-to material for prototyping and end-use products.

Reasons to choose Ultimaker PP

Ultimaker PP material properties make it popular with engineers and manufacturers worldwide. For example, the filament's chemical resistance makes it ideal for 3D printing bottles and containers as functional prototypes that can hold a liquid product.

- Chemically resistant to a wide range of acids and bases, including industrial cleaning agents

- Retains its form after torsion, bending, or flexing

- High electrical resistance for good electrical insulation

- Low density, resulting in lightweight parts

Properties:

Choose Ultimaker PP filament and your 3D printed part will have some impressive properties:

- High strength-to-weight ratio

- Shore D hardness of 45

- 27.1 kJ/m² izod impact strength

- 200% elongation at break

Applications:

Ultimaker PP material is often chosen for the following applications:

- Functional prototyping

- Tooling

- End-use parts

- Concept models

Durable and rugged

Living hinge on a container PP has high fatigue resistance and does not break when repeatedly bent. Clamps and living hinges can remain functional over the lifetime of the part.

Prototypes simulate end products

PP is widely used in end products. Create functional prototypes and print in the same material as the end product for the ultimate in prototyping.

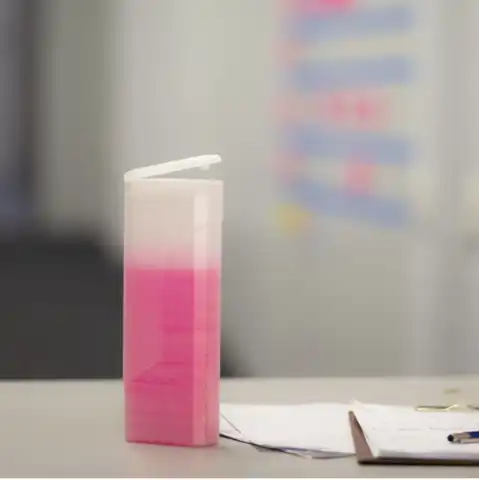

Translucent and lightweight

PP features good layer bonding, and it is an excellent choice when the design requires transfer of light for aesthetic or other reasons.

Compatibility

Ultimaker PP can be printed on the Ultimaker S5, Ultimaker S3, and Ultimaker 3. It is officially supported for single-extrusion prints.