Voltera NOVA Direct Ink Write Printing Philippines

Print flexible electronics using conductive inks like copper, silver, carbon, and more. Prototype quickly using NOVA’s additive electronics technology.

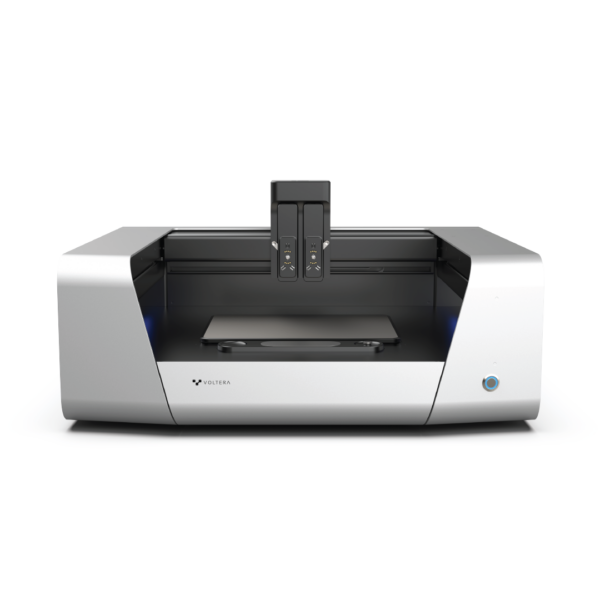

Voltera NOVA

The future of printed electronics

Unlock new opportunities and accelerate research and development with high-resolution printing using a range of functional materials and screen-printable inks.

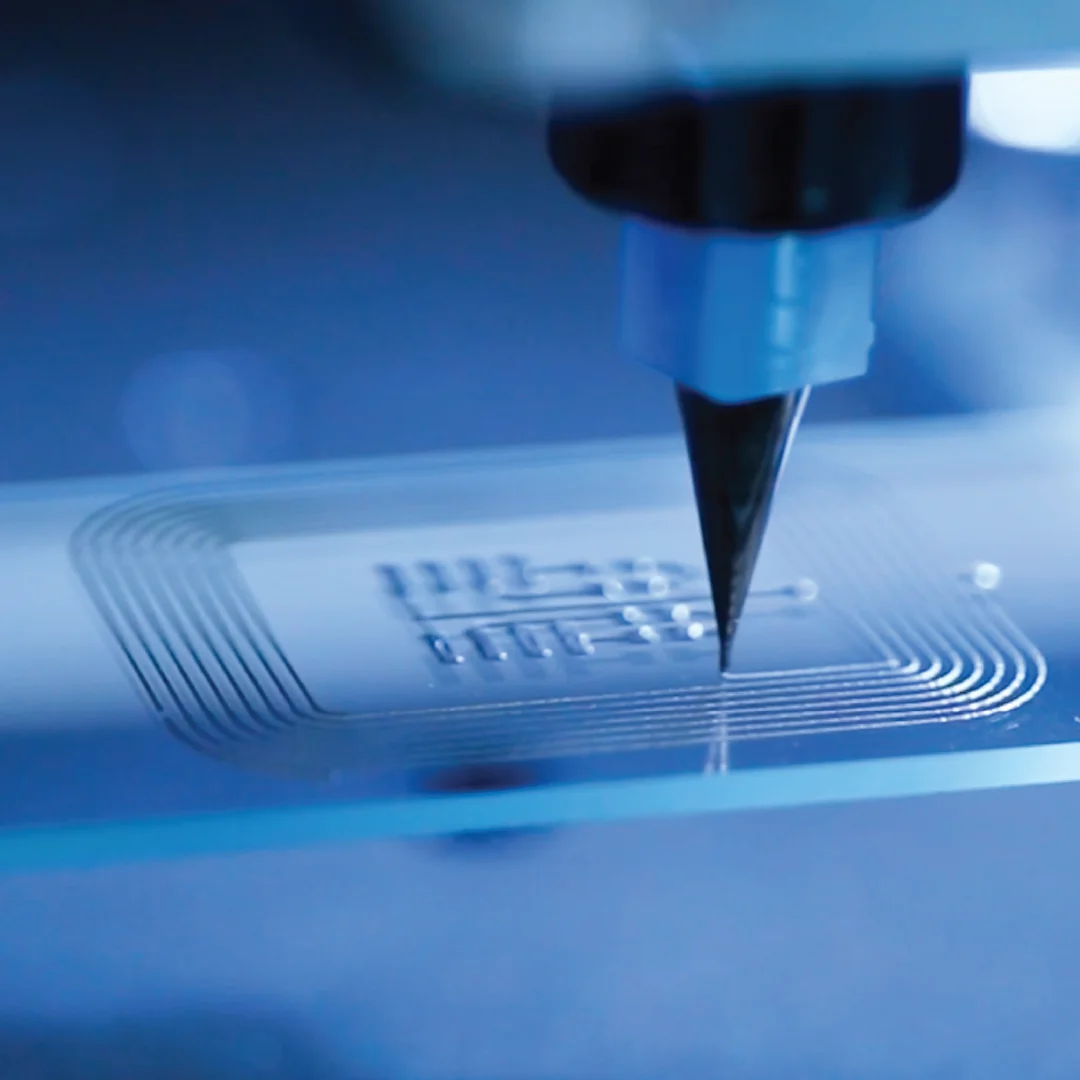

Meet NOVA — a modular dispensing system

Unlock new opportunities

Be first to explore what’s possible with printed electronics and push the limits of functional materials research and development.

Streamline research and development

Change designs on the fly and get immediate feedback on new ideas, accelerating R&D timelines and reducing costs.

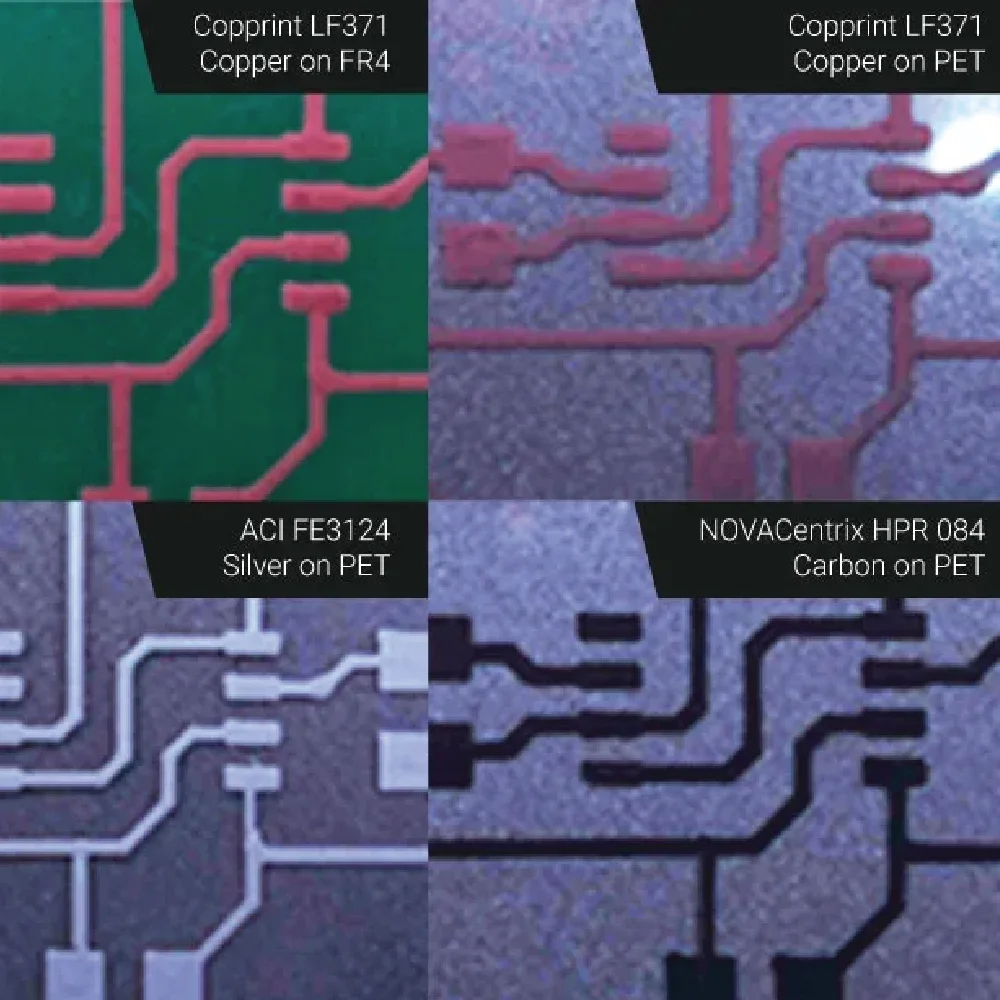

Total material freedom

Experiment with a wide range of substrates and screen-printable materials. Validate designs in the lab and seamlessly transition to production equipment.

No experience required

The intuitive user experience alleviates internal training challenges and allows anyone to achieve the results they are looking for.

What can NOVA do?

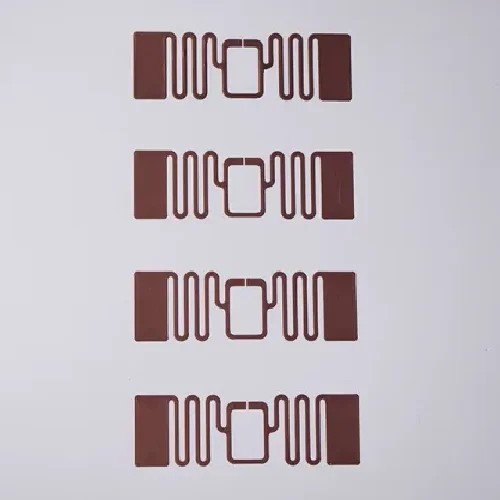

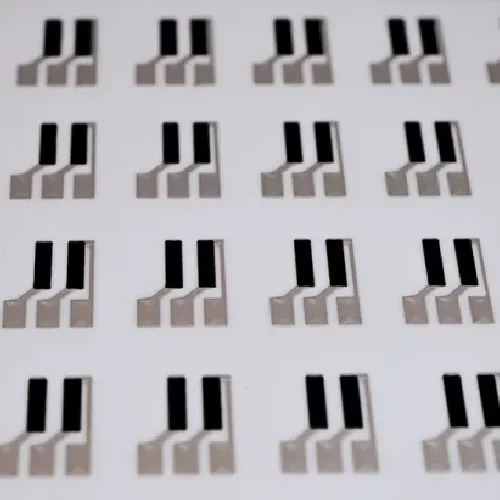

RFID Tag

Substrate

Paper

Printed material

Copprint LF301 Nano Copper Ink

Nozzle size

Nordson EFD 0.004" Optimum chamfered tip

Print time

~48 min

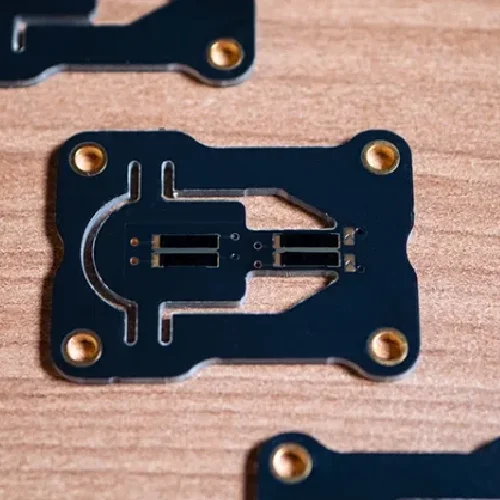

Ceramic PCB

Substrate

Alumina

Printed material

NovaCentrix HPS-FG57B Silver Flake Ink

NovaCentrix HPR-059 Carbon Ink

Nozzle size

Subrex 150 µm Micro Precision Nozzle

Print time

~35 min

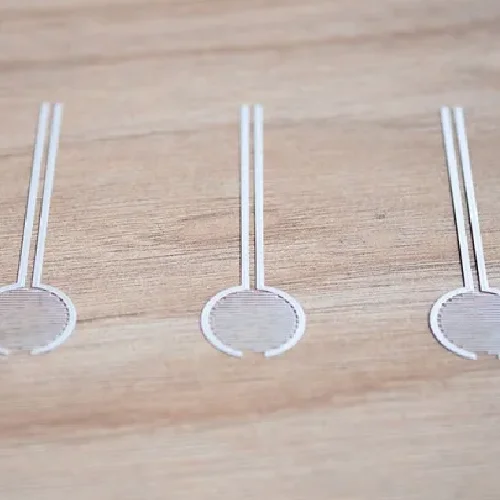

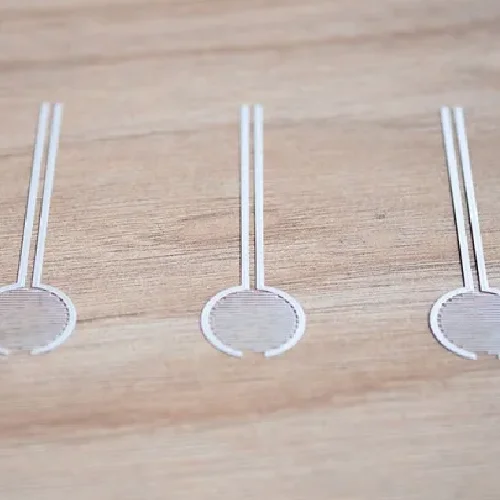

Strain gauge

Substrate

FR4

Printed material

NovaCentrix HPR-059 Carbon Ink

Nozzle size

Subrex 150 µm Micro Precision Nozzle

Print time

~15 sec

Force Sensitive Resistor (FSR)

Substrate

PET

Printed material

ACI RD0142A Conductive Ink

Nozzle size

Subrex 100 µm Micro Precision Nozzle

Print time

~20 min

Flexible Hybrid Electronics (FHE Circuit)

Substrate

Kapton

Printed material

ACI RD0142A Conductive Ink

Nozzle size

Nordson EFD 0.004" Optimum chamfered tip

Print time

~15 min

NOVA benefits

Streamline research and development with direct-ink-write dispensing

No tooling

Change designs on the fly and iterate without screens or stencils, eliminating delays and reducing costs.

No waste

Print only what’s needed, conserving valuable material.

No cleanup

Material is contained throughout the printing process, simplifying cleaning and handling procedures.

90% faster

iteration time

96% reduced

material costs

Explore new possibilities with high resolution, closed-loop dispensing

Increased material options

A wide range of compatible viscosities unlocks enhanced performance and material characteristics, from inks to gels and pastes.

Reduced risk

Validate designs and materials in the lab and seamlessly transition into production with scalable printing technologies.

Repeatable results

Achieve consistency and high precision with integrated closed-loop pressure feedback, and temperature controlled dispensing.

100 µm

Line width*

1,000 - 1,000,000 cps

Viscosity range

* Dependent on material and nozzle.

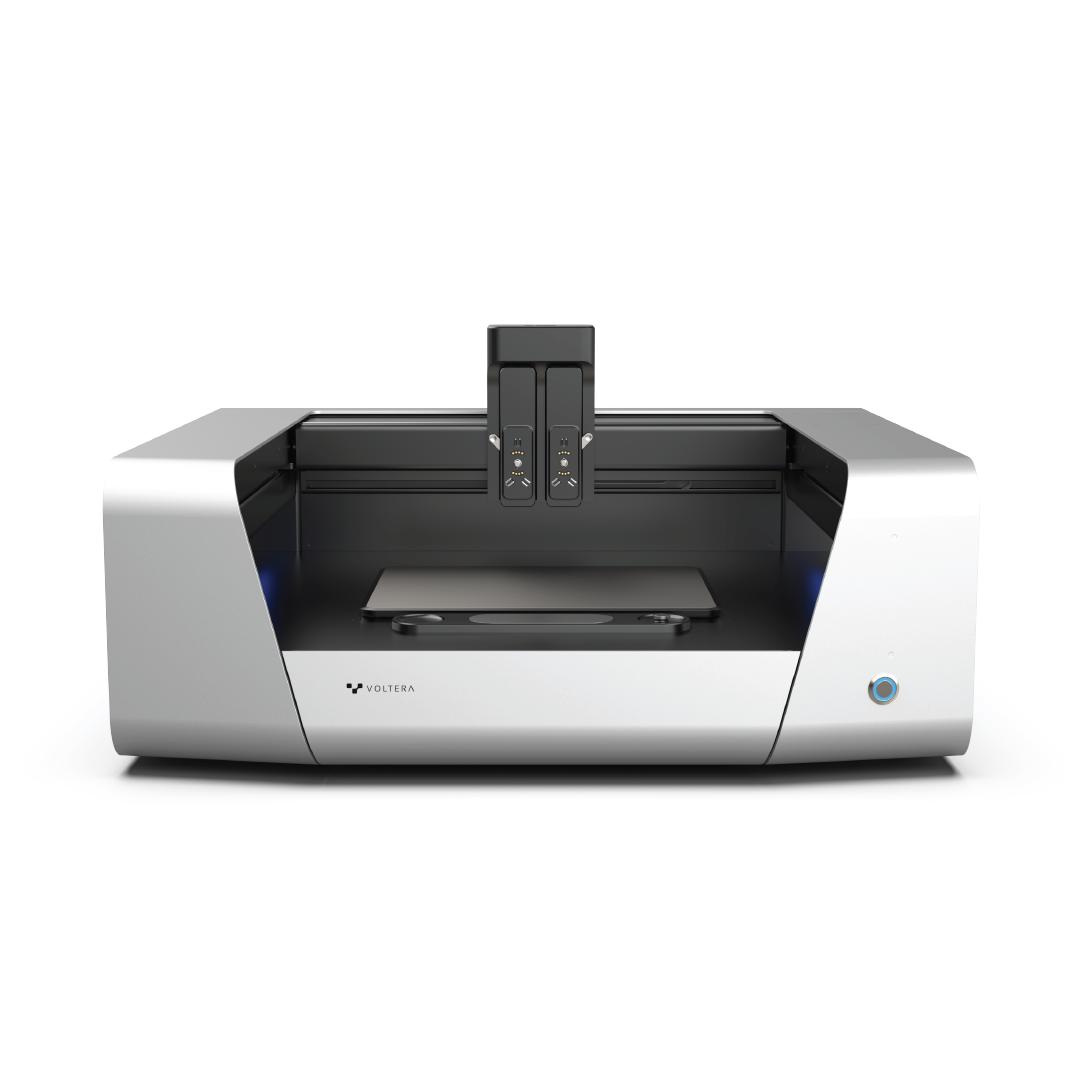

Adapt to any application with a large, configurable print area

Rigid substrates

Secure your rigid substrates of all shapes and sizes with provided threads onto the 40 mm x 40 mm mounting grid.

Compliant substrates

Secure your conformable substrates with NOVA’s porous titanium vacuum table which applies uniform suction.

Unconventional substrates

Develop application-specific fixturing for unconventional substrates using the mounting grid features.

220 mm x 300 mm

Print area

40 mm x 40 mm, M5

Mounting grid

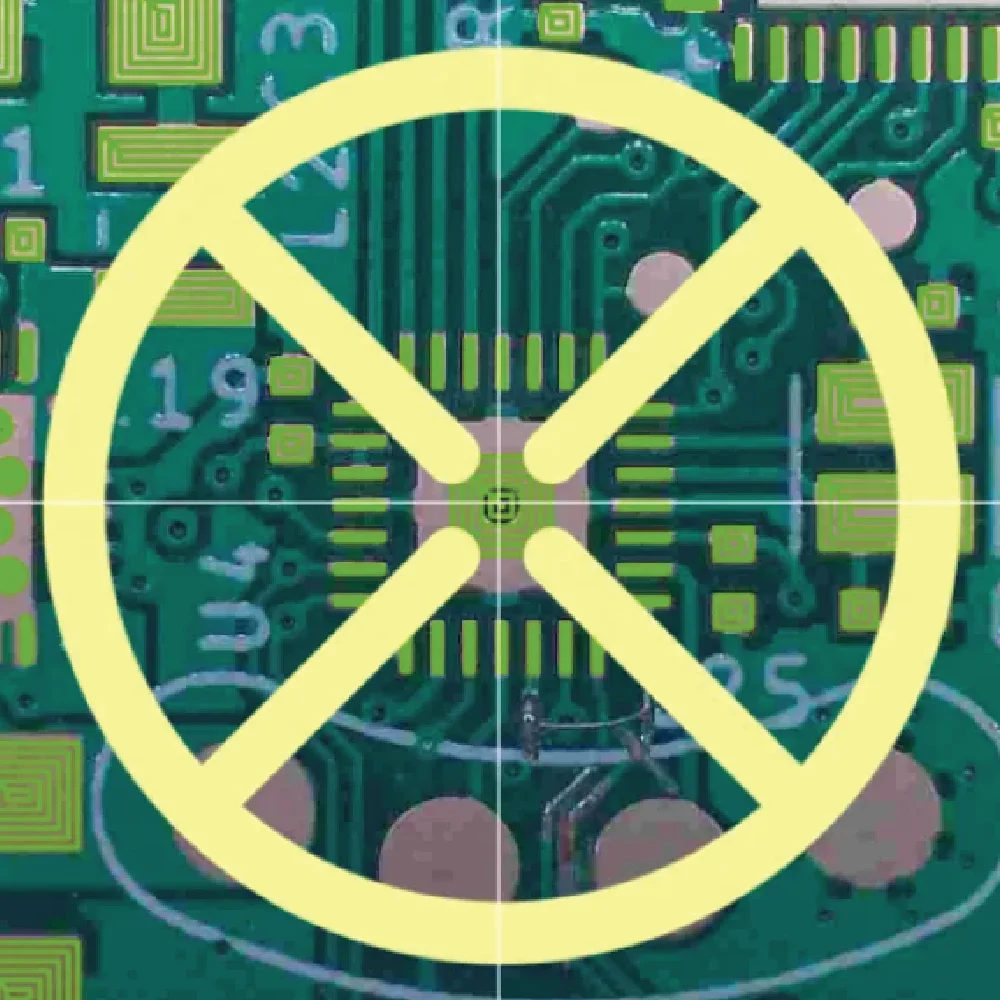

Ensure print accuracy with integrated computer vision

Eliminate registration errors

Accurately position and align patterns with augmented reality overlay.

Optimize print quality

Find the ideal height, pressure, and print settings with a dedicated material calibration workflow.

Simplify reporting

Capture images for analysis, measurements, and documentation.

17 µm/pixel

Resolution*

Image size

* Dependent on substrate height

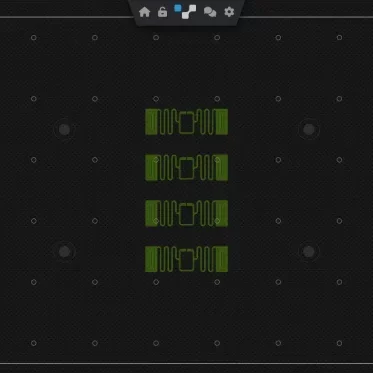

Easy-to-use software

Smooth onboarding

Guided workflows, walk-through videos, and user profiles in the browser-based app set you up for success.

Seamless cooperation and independent research

Browse, create, and modify saved profiles for materials and substrates with the central materials library.

In-app access to support

Connect directly with Voltera support via live, in-app chat.