Selective Laser Sintering is widely used in electronics industry. Thanks to the choice of materials, as in the example below, it can be used for stiff and elastic elements.

3. Medicine

The freedom of shape and no need of using support structures makes SLS a perfect choice for medical applications, such as pre-surgical training model or prototyping medical devices.

4. Fashion and art

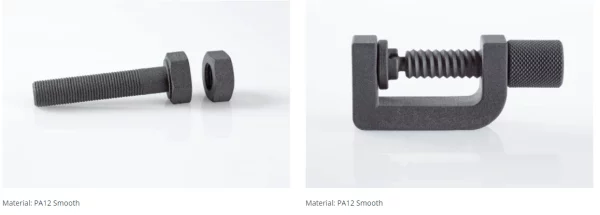

There are six materials in Sinterit’s offer and we are constantly working to extend the offer. You can choose from powders soft almost like fabric through wearable TPE to hard and stiff materials such as PA12 Smooth or PA11 Onyx.

Now, you can think of how Selective Laser Sintering can help you and your business. You’re now able to decide what material and what application you would use this technology.

Don’t hesitate to send us an email at [email protected] for inquiries.

Source: Sinterit