Sub-Total: ₱0.00

Blog Posts

Unlocking the Power of 3D Scanning: Shining 3D

In today’s world of digital design and rapid prototyping, 3D scanning technology has become an essential tool for industries ranging from manufacturing and engineering to...

The Amazing World of UV Printers: Why ArtisJet is Changing the Game for Hobbyists and Small Businesses

If you’ve ever wanted to print your designs directly on wood, glass, metal, or even your favorite phone case, then you’ve probably come across UV...

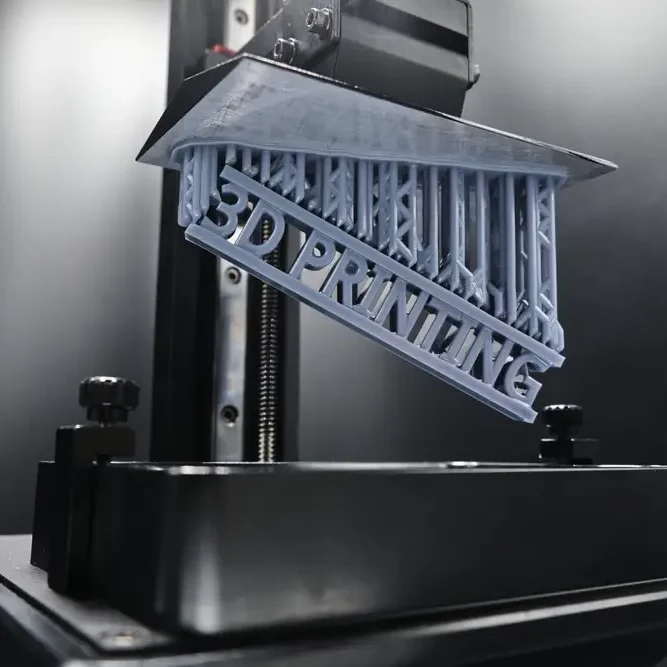

Beginner’s Guide to Resin 3D Printing: Dive Into the Magic of Liquid to Solid

If you’ve ever watched a slow-motion video of resin 3D printing, you probably thought, “Is this wizardry or science?” Spoiler: it’s science—but it feels like...

Flux Ador – The World’s First Color Laser Cutter with Full-Color Printing in the Philippines

Flux Ador: The World’s First Color Laser Cutter with Printing If you’ve ever wished your laser cutter could also print in vibrant color, your wish just...

Laser Cutter Technology – Best Brands & Buying Guide

Laser Cutter Technology: How It Works, Benefits, and Top Brands Laser cutting has revolutionized manufacturing, art, and product design. Whether you’re a hobbyist creating intricate...

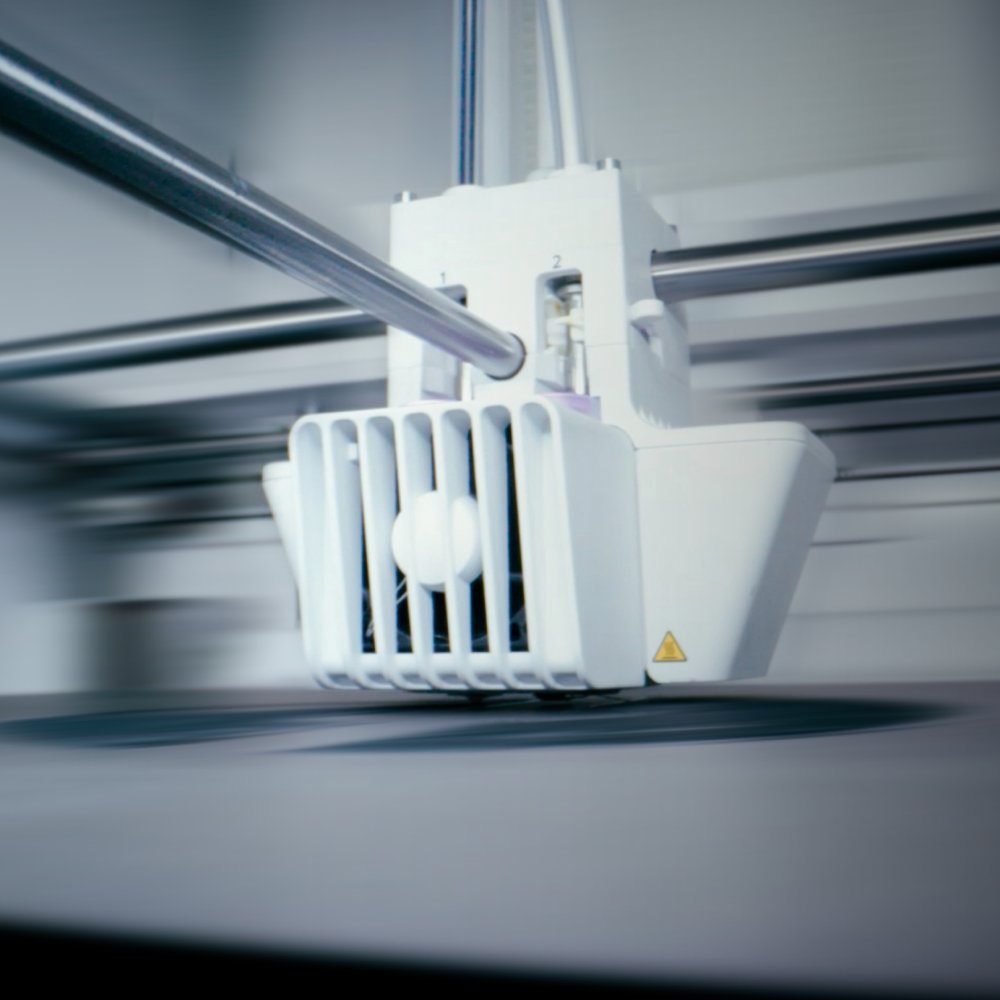

Unleashing the Beast: Why the UltiMaker S8 Is the Future of Professional 3D Printing

What's New in the UltiMaker S8? Game-Changing Features You'll Love Imagine a machine so precise it captures the essence of engineering dreams, yet so fast...

NEW Bambu Lab H2D – at Puzzlebox 3D

Bambu Lab H2D: The Future of 3D Printing Is Here – at Puzzlebox 3D! Bambu Lab has once again raised the bar for innovation in...