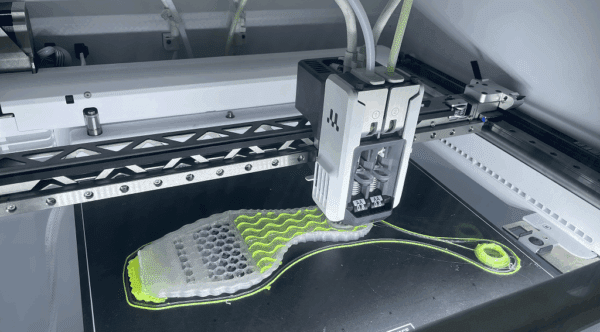

UltiMaker’s design makes it especially effective for footwear production with flexible materials. Its enclosed chamber and precise thermal control ensure consistent TPU performance, while the dual gripper direct drive extrusion system minimizes clogging issues common with soft filaments. Combined with multi-material printing for complete shoe builds and Digital Factory software for seamless workflow management, it delivers reliable, scalable results.

The footwear industry is entering a new era. With the rise of advanced 3D printing, sustainable materials, and decentralized production models, brands and innovators are beginning to rethink how shoes are designed, produced, and delivered. This breakthrough approach not only reduces waste and environmental impact but also opens the door to personalized, on-demand footwear tailored to individual needs.

Across Europe and beyond, innovation labs and research centers are proving how technologies like FDM (Fused Deposition Modeling) 3D printing and recyclable materials such as TPU (Thermoplastic Polyurethane) can transform footwear manufacturing from the ground up.

The Future of Footwear Is Being Rewritten

The footwear industry is experiencing one of the most significant breakthroughs in decades. Instead of relying solely on mass production and long, globalized supply chains, innovators are turning to 3D printing technologies to create sustainable, customized, and on-demand footwear.

This shift is more than just a technological upgrade—it represents a complete reimagining of how shoes are designed, produced, and delivered. By adopting additive manufacturing, footwear companies can:

-

Reduce waste by producing only what is needed.

-

Cut carbon emissions by enabling localized manufacturing.

-

Enhance comfort and performance through personalized designs.

-

Use recyclable or compostable materials to promote circular production.

From UltiMaker’s Factor series to Bambu Lab’s high-speed printers and Flashforge’s versatile systems, today’s 3D printing solutions are unlocking the potential for sustainable footwear manufacturing on a global scale.

Footwearology in Barcelona: A Living Example of Breakthrough Innovation

One of the clearest examples of this new direction comes from Footwearology, an innovation lab and academy based in Barcelona, Spain. Dedicated to reshaping the global footwear supply chain, Footwearology blends research, consulting, and hands-on training to equip professionals with future-ready manufacturing skills.

Its fully equipped lab includes state-of-the-art 3D knitting machines and FDM (Fused Deposition Modeling) 3D printers, making it a hub for experimenting with new materials and methods. At the heart of their mission is a bold goal:

to enable localized, sustainable, and personalized footwear production.

CEO Nicoline van Enter explains their approach:

“FDM allows for affordable production and better sustainability compared to powder or resin-based methods, especially for flexible items. Our materials can be fully recycled or compostable, which is important for us.”

Rather than treating 3D printing as a prototyping tool, Footwearology embraces it as a production technology. Their vision is a decentralized “network production” model where regional hubs produce footwear close to the consumer—cutting waste, reducing carbon emissions, and supporting mass personalization.

The Role of TPU in Next-Generation Footwear

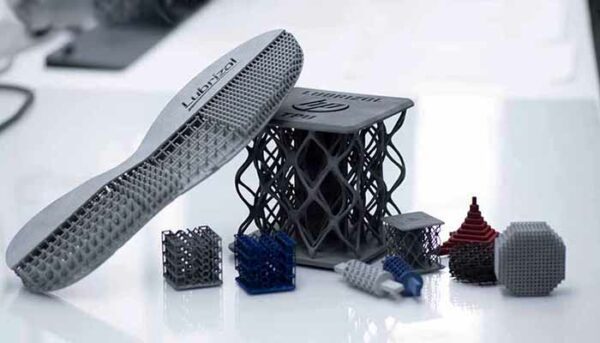

A key part of Footwearology’s work—and a broader footwear trend—is the use of Thermoplastic Polyurethane (TPU).

TPU is durable and flexible, making it perfect for wearable applications. Its recyclable nature supports circular economy practices, while variable material properties allow for customized cushioning and stiffness tailored to individual needs.

Footwearology collaborates with material manufacturer Recreus to develop TPU filaments with different densities, weights, and even custom colors. This material innovation ensures footwear can be both functional and sustainable—a critical breakthrough for the industry.

UltiMaker: Industrial Reliability for Sustainable Footwear

Footwearology’s choice of the UltiMaker Factor 4 underscores the importance of reliable hardware for footwear production. Having collaborated with UltiMaker in early development, the lab recognized Factor 4’s ability to handle demanding flexible materials like TPU.

Why UltiMaker is a footwear breakthrough:

With these capabilities, UltiMaker has proven itself as a production-ready system for flexible, wearable footwear components.

“We’ve always valued how easy UltiMaker is to use – especially how effortlessly the print core can be changed.”

Bambu Lab: High-Speed Customization

While UltiMaker focuses on industrial-grade reliability, Bambu Lab brings speed and automation into the spotlight. Known for their high-speed, multi-material FDM printers, Bambu Lab systems are enabling footwear manufacturers to shorten design cycles and scale custom production.

For footwear makers, Bambu Lab provides:

Bambu Lab empowers footwear makers with rapid prototyping and high-speed printing, giving them the ability to iterate designs quickly. Its multi-material and color support expands creative freedom, while automated filament systems keep production smooth and efficient

.

For smaller workshops and local production hubs, Bambu Lab represents a way to quickly move from concept to finished shoe components, making it a powerful tool in the decentralized footwear model.

Flashforge: Opening Doors for Designers and Innovators

Flashforge has become a go-to brand for accessible, versatile 3D printers—especially in design schools, R&D labs, and small-scale manufacturing. In footwear, this means enabling more creators to explore the potential of additive manufacturing.

Flashforge contributions to footwear innovation include:

Flashforge offers user-friendly systems that make 3D printing accessible for designers and students. Its affordable hardware supports experimentation and small-batch production, while compatibility with flexible filaments enables the creation of wearable prototypes with ease.

By democratizing 3D printing, Flashforge plays a vital role in preparing the next generation of footwear innovators.

Toward a Sustainable, Decentralized Footwear Industry

From Barcelona to global markets, the message is clear: the breakthrough in footwear manufacturing is happening now. With Footwearology’s pioneering work and the enabling technologies of UltiMaker, Bambu Lab, and Flashforge, the industry is moving toward:

The future of footwear manufacturing is centered on localized hubs that produce on demand, enabling mass personalization tailored to individual biomechanics. By adopting circular design models with recyclable and compostable materials, these systems reduce waste and emissions, fostering a more sustainable and efficient supply chain.

This decentralized model has the power to redefine footwear manufacturing—making it not only smarter and more efficient, but also more responsible!

Conclusion: A Breakthrough Worth Following

The footwear industry’s breakthrough moment is here. No longer tied to outdated mass production methods, innovators are proving that shoes can be custom, sustainable, and locally made with the help of advanced 3D printing.

With UltiMaker’s reliability, Bambu Lab’s speed, and Flashforge’s accessibility, the tools for this transformation are already in the hands of creators. And with labs like Footwearology in Barcelona leading the charge, the future of footwear is being rewritten—one sustainable step at a time.

Posted in Applications, Blog