Chemical-resistant materials are vital for many 3D printing applications. Corrosive chemicals can’t permeate their surface or cause degradation, making them ideal for industrial or end-use parts. There are several different chemical-resistant materials to choose from, each with specific benefits.

Why is chemical resistance important?

“Chemical resistance” means that materials can fulfil their function, even in harsh working environments. Chemical-resistant materials don’t require surface treatment; they are able to withstand exposure to chemicals such as bases, solvents, and acids.

Without chemical-resistance, a material may erode, soften, or become misshapen. This is due to the chemical’s molecules diffusing within the material and pushing the polymer chains apart. When this happens, it reduces functionality, and may damage other surrounding parts.

Common uses of chemical-resistant materials

Chemical-resistant materials play an important role in packaging applications, particularly in the packaging of cleaning agents, reagents, and other chemicals. They’re also useful for manufacturing tooling. During use, jigs and fixtures are often exposed to chemicals (liquid, gas or solid). Chemical resistance ensures they don’t degrade over time.

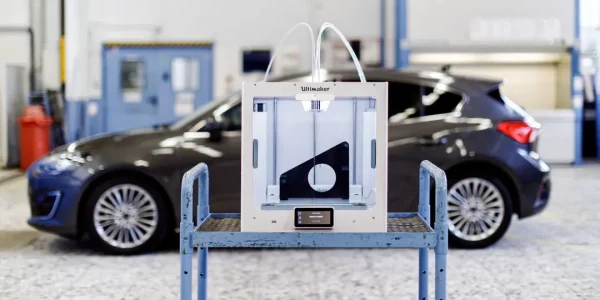

Some automotive parts are created using chemical-resistant materials

What else should you know?

The main factors that influence a polymer’s chemical resistance

A material’s chemical resistance is impacted by several different factors. These include:

- the molecular structure of the polymer

- the time of exposure to a chemical

- the temperature at the time of exposure

- the nature of the chemical

- the stress applied to the material

Chemical resistance depends on the application

Materials are usually only resistant to certain types of chemical. For example, Nylon isn’t adversely affected by acetone, but can be damaged by water. Conversely, PETG isn’t affected by water, but acetone will degrade it. Every material has different properties, and it’s vital to choose the right one for the job.

Materials with good chemical resistance

Several materials have excellent chemical resistance, such as PP, PVDF, and Nylon. PETG is unaffected by water-based chemicals, and (like CPE and CPE+) has good resistance against common chemicals such as alcohol and weak acids.

| PP | Most chemicals (except acetone and fluorinated/chlorinated chemicals) |

| PET(g) / CPE(+) | Alcohols (EtOH, IPA), water, acids and bases |

| Nylon | IPA, Solvents (acetone, glycerol) |

| ABS | Water, some acids and bases, alcohols |

| TPU | Water (salts), glycol and fuels |

| PC | Water and alcohols |

| PLA / Tough PLA | Water |

| PVDF | Solvents (chlorinated, aliphatic, aromatic), strong acids, weak bases, halogens, strong oxidants |

Things to note when using chemical-resistant materials

- It’s vital to consider temperature, as most diffusion processes are temperature dependent

- Amorphous thermoplastic polymers, when exposed to chemicals, may crack. This can lead to part failure

- When choosing a material, think about the concentration of the chemicals, and the mechanical load

Our chemical-resistant material partners

Arkema

Arkema FluorX™ is a tough, semi-crystalline fluoropolymer made from Arkema’s Kynar® PVDF. It is formulated for printability, and is a great option for parts subjected to demanding conditions, such as solvents, acids, fire, and UV radiation.

“Kynar® PVDF is the material of choice for many harsh chemical environments,” Steven Serpe, Market Manager, Specialty Powders and 3D Printing at Arkema, said. “Fluoropolymers are well known for chemical resistance, but ability of Kynar® PVDF to be easily processed via many methods including 3D printing makes it stand out in the chemical processing industry for applications like piping, lining, pumps, and other fluid handling equipment.”

BASF

PP GF30 contains special glass fibers that are designed for filament making and 3D printing. This will ensure the printed objects are functionally working under certain temperature and mechanical loads.

“Chemical resistance is the degree to which your printed part retains its mechanical properties and shape when it comes in contact with chemicals or solvents. For example, PAHT CF15 has chemical resistance properties against lubricants, whilst ASA shows resistance properties against cleaning agents and Ultrafuse 316L against all organic solvents among others,” Roger Sijlbing, Head of Sales Additive Extrusion Solutions at BASF, said. “In many cases the chemical resistance is not only a question of material & chemical combination but includes rather application temperatures and dwell time. BASF 3D Forward AM is working on an overview for end-users to assess the chemical resistance of our materials for FFF printing. Currently our chemical experts provide information concerning the chemical resistance of our products on request.”

DSM

Arnitel® ID 2045 is a highly flexible TPC (thermoplastic copolyester) that can be used in a broad range of applications. It has better UV and chemical resistance compared to others of its type, such as TPU (thermoplastic urethane).

Solvay

Solef® PVDF AM Filament is a tailor-made fluorinated semi-crystalline additive manufacturing material for best printing results of parts that need chemical resistance, high thermal and environmental stability, and good mechanical properties.

“Solef(R) PVDF AM Filament is not only resistant to a broad range of harsh chemicals such as inorganic and organic acids, aliphatic and aromatic hydrocarbons, crude oil, fuels and alcohols, and ethers, but also intrinsically fire retardant, UV and temperature resistant up to 130°C,” Sophia Song, Business Incubation – Additive Manufacturing at Solvay, said. “This unique combination of properties with the ease of printing the material enables the access to a broad range of applications.”

Interested in learning more about Ultimaker’s temperature-resistant material partners? Visit the chemical-resistant materials page on the Ultimaker Marketplace.

You can also explore Ultimaker’s range of 3D printers that are compatible with chemical-resistant materials.