Learn the fundamental steps to successfully print this dissolvable support material and why it’s necessary for complex dual-extruded parts.

PVA filament is a critical material for creating complex parts on a dual extrusion 3D printer. If you aren’t using this material yet, you need to be. These tips and tricks for printing with PVA will guide you to success.

What is PVA Filament?

When it comes to 3D printing filament, PVA stands for PolyVinyl Alcohol. PolyVinyl Alcohol is the same material used in laundry detergent pods that dissolve in the wash, with the same principle being used to create dissolvable support material. Most glue sticks are PVA as well, so the filament is essentially a printable, solid glue stick.

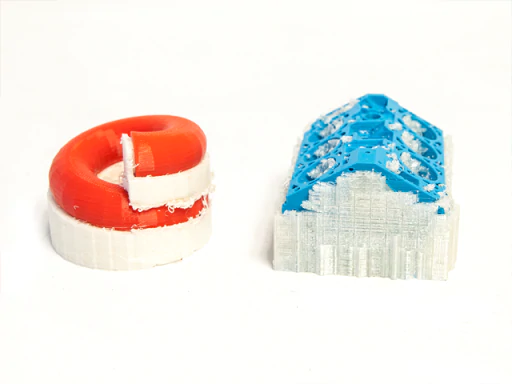

This model would have been extremely difficult to print successfully without dissolvable supports.

When Should You Use PVA Filament?

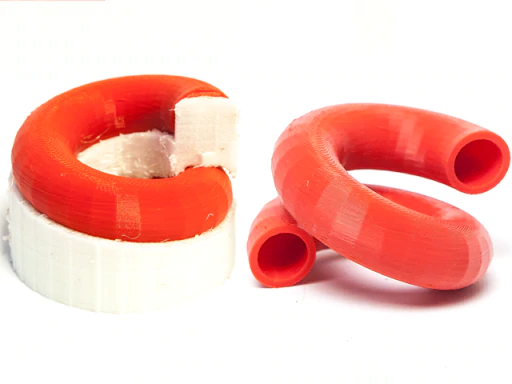

First, to use PVA, you need a printer capable of dual extrusion, and you should only really use PVA with PLA as your main material. PLA 3D filament prints at a similar temperature as PVA which make them a perfect pair. Dissolvable supports really shine when your model has intricate details, internal cavities that you wouldn’t be able to clear same-material support from, or overhangs on your model that you want to avoid having support scarring on. Think about having to print a tubular spiral with auto-generated same material support; at a certain point you won’t be able to break away all the internal support, and the outside of the model is going to have scars from where the support material was attached – but, by using PVA dissolvable support, you just give it a quick soak and sit back and wait for it to work its magic.

The left model would be impossible to print without dissolvable support. The right would have a lot of support scarring as well.

When Should You Use A Different Support Material?

If you’re printing other 3D filaments like ABS, PETG, Nylon, or TPE, which all print at a higher temperature or don’t stick well to PVA filament, use a different support material or even just use same-material support. Like HIPS, the perfect support for ABS, PVA does cost more than regular build materials, so if you’re printing a fairly simple model, a model with easy to clean supports, or you plan on finishing your 3D print anyways, then stick with printing your supports with the same material.

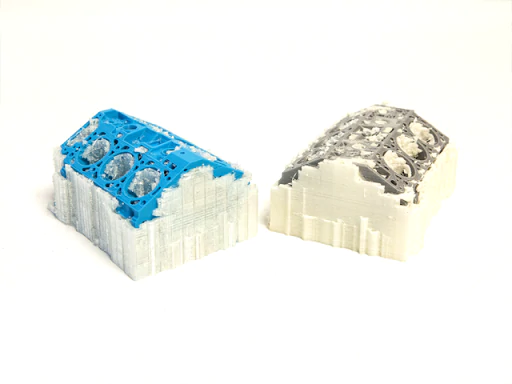

ABS printed with HIPS support material.

Best Printing Temperatures for PVA Filament

The brand of filament you’re using affects the printing temperature for PVA. For MatterHackers PVA filament, print at 185±15°C, or if you’re using Ultimaker PVA, print it at 215±5°C. Don’t push it much higher than these temperatures, because PVA is very prone to cooking and carbonizing in the nozzle. In other words, it clogs easily, so make sure you keep your printing temperatures low and retract the filament from the nozzle when not in use.

Dry PVA Filament Before Printing

Like nylon, PVA is hygroscopic, which means it absorbs water from the air easily. When you first open your roll of PVA filament, stash the desiccant that it came with so you can store it in a sealed container when you aren’t using it. If you happen to forget to store it and the roll sits out for too long, you will notice your PVA hissing and popping as you print, indicating it absorbed water. All is not lost, simply dry it in the oven for a couple hours to pull all the moisture out and then store in a sealed container.

The engine on the left used dried PVA; you can see the support is slightly translucent and almost clear. The right engine used wet PVA for support; its yellowish-white and completely opaque.

The engine on the left has PVA that was dried in an oven before printing. The engine on the right used PVA filament left in the open air.

Dissolving PVA Filament

The best way we have found for cleaning off PVA support material is to break off as much as possible before soaking – be careful not to damage small parts that may be encased in PVA. Next, submerge your print in a container with warm water. You don’t want the water to be boiling hot, as it could damage your other material, but the hotter it is the quicker it’ll dissolve. A good approximation is: if you wouldn’t take a bath in it, don’t put your print in it.

Left with PVA support still attached, right with the PVA dissolved.

This blog is originally made by Matterhackers: https://www.matterhackers.com/news/how-to-succeed-when-3d-printing-with-pva-support-material