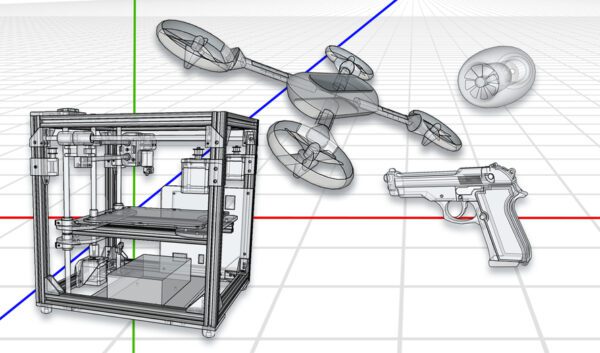

Additive manufacturing has become a strategic capability for modern defense organizations. No longer limited to prototyping, military forces now rely on 3D printing for producing mission-critical components, battlefield-ready spare parts, and advanced tools at the point of need. This speed and flexibility offer enormous advantages, but they also bring a new challenge: security.

In defense, where technological sovereignty and operational readiness are paramount, a single breach in the digital manufacturing chain could compromise national security. Sensitive designs might be stolen, sabotaged, or manipulated, while compromised hardware could disrupt mission-critical operations. For this reason, secure 3D printing in defense is not just a feature — it is a strategic requirement.

Secure 3D Printing in Defense: Protecting Mission-Critical Designs and Operations

Additive manufacturing has become a strategic capability for modern defense organizations. No longer limited to prototyping, military forces now rely on 3D printing for producing mission-critical components, battlefield-ready spare parts, and advanced tools at the point of need. This speed and flexibility offer enormous advantages, but they also bring a new challenge: security.

In defense, where technological sovereignty and operational readiness are paramount, a single breach in the digital manufacturing chain could compromise national security. Sensitive designs might be stolen, sabotaged, or manipulated, while compromised hardware could disrupt mission-critical operations. For this reason, secure 3D printing in defense is not just a feature — it is a strategic requirement.

The Security Risks of Military 3D Printing

Every stage of the additive manufacturing workflow presents potential vulnerabilities. On the digital side, design files can be intercepted, copied, or maliciously altered. A small change to a CAD file could introduce defects into aircraft parts, vehicle components, or weapons systems, with consequences that might only become apparent during deployment. On the hardware side, unprotected printers are susceptible to tampering, unauthorized access, or firmware manipulation, all of which can undermine the reliability of printed parts.

The risks of neglecting security in defense manufacturing are profound. Unauthorized access to part libraries could expose classified technology. Malicious file alterations could lead to mechanical failures in the field, threatening soldier safety and mission success. Even downtime caused by cyberattacks or compromised equipment could erode military readiness.

The Four Pillars of Defense-Grade 3D Printing Security

Across defense organizations, secure additive manufacturing revolves around four priorities. Confidentiality ensures that sensitive designs — from drone components to weapons parts — remain protected from external access. Integrity guarantees that parts are printed exactly as intended, with no hidden alterations or embedded weaknesses. Availability protects against downtime, ensuring printers remain ready to deliver mission-critical parts at any time. Finally, sovereignty gives military organizations full control over their processes and data, preventing reliance on third-party providers or foreign jurisdictions that could compromise independence.

UltiMaker’s Approach to Defense-Ready Security

UltiMaker has embedded these principles into both its hardware and software, making its ecosystem a trusted choice for high-security environments. On the software side, UltiMaker aligns with global standards such as ISO/IEC 27001 and ISA/IEC 62443-4-2, ensuring compliance with strict information security and industrial cybersecurity requirements. Its platforms undergo independent security audits, and features like role-based access and offline operation allow defense organizations to operate printers within air-gapped or classified environments.

On the hardware side, UltiMaker printers are manufactured in Europe under rigorous quality controls, incorporating tamper-resistant designs and secure firmware updates signed with private keys. Built-in firewalls limit access to authorized personnel, while the removal of built-in cameras in Secure Line printers further reduces attack surfaces. These measures give defense operators the assurance that their printers are protected against both physical and digital threats.

The Defense-Ready Lineup: Factor 4, S6 Secure, and S8 Secure

To meet the unique requirements of defense and military applications, UltiMaker developed a suite of solutions that balance industrial-grade performance with defense-grade security.

An advanced industrial 3D printer built for high uptime, large-format production, and demanding materials. With precise environmental controls, reinforced architecture, and automated calibration, the Factor 4 is ideal for printing durable parts that meet military performance standards. It is a powerful tool for organizations needing rapid production of critical components with reliable repeatability.

A secure variant of the widely trusted S6 platform, the S6 Secure is engineered for classified environments where connectivity must be tightly controlled. It features tamper-resistant firmware, compliance with NATO security frameworks, and the ability to operate entirely offline, making it suitable for deployment in sensitive defense facilities.

Building on the strengths of the S6 Secure, the S8 Secure offers a larger build volume while maintaining the same strict security features. It enables defense organizations to produce bigger, mission-ready components without sacrificing data sovereignty or protection from cyber threats.

Together, these systems form a defense-ready ecosystem that empowers military organizations to adopt additive manufacturing at scale without compromising operational security.

Building a Defense-Ready 3D Printing Ecosystem

A secure printer is only one part of the solution. Defense organizations must implement a holistic approach that classifies digital assets by sensitivity, enforces encrypted workflows, and restricts access to authorized personnel only. Secure facilities, trusted supply chains, and strict update protocols are essential. Just as important is training: personnel must understand secure handling of classified design files and know how to respond to incidents quickly and effectively.

By combining secure hardware and software with clear policies and procedures, military organizations can build an additive manufacturing ecosystem that supports both innovation and protection.

Conclusion

As modern defense strategies increasingly rely on additive manufacturing, secure 3D printing in the military has become mission-critical. Protecting intellectual property, ensuring the reliability of printed parts, and maintaining sovereignty over production are as vital as speed and flexibility on the battlefield.

With the UltiMaker Factor 4, S6 Secure, and S8 Secure, defense organizations gain the ability to innovate rapidly while maintaining the highest levels of operational security. In an age where conflicts extend into the digital domain, protecting the integrity of 3D printing is as essential as the missions it supports.