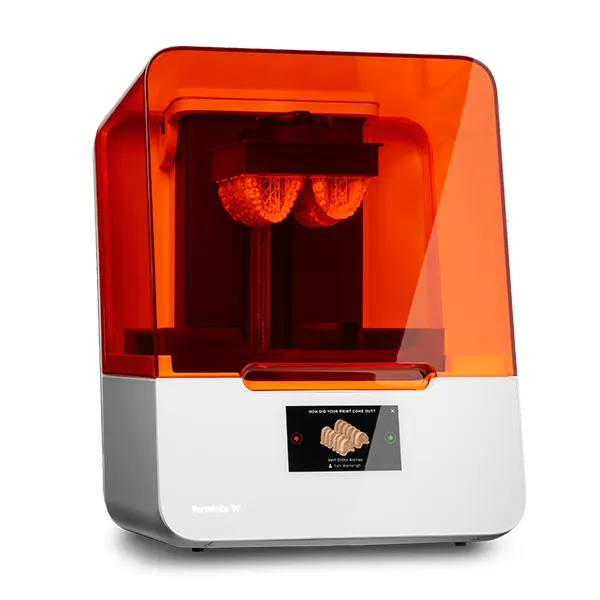

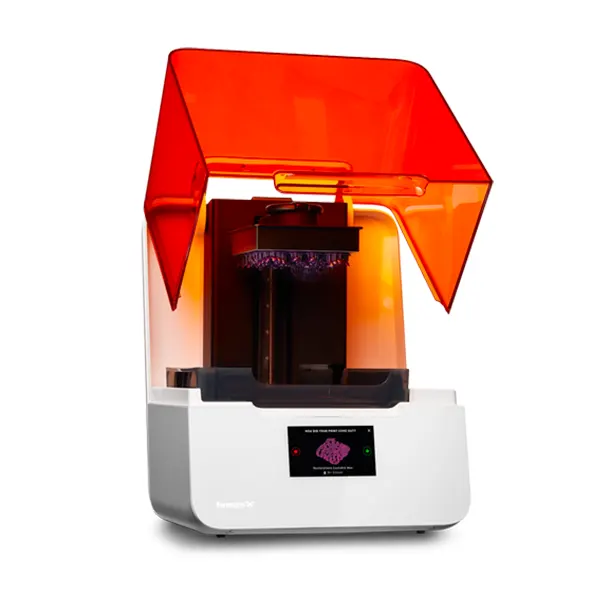

Formlabs Form 3B

The Form 3B is an advanced desktop 3D printer optimized for biocompatible materials. Our precise, reliable ecosystem takes the guesswork out of dental fabrication so faster workflows are just a few clicks away.

More Smiles, All Around

The Form 3B is an advanced desktop 3D printer optimized for biocompatible materials. Our precise, reliable ecosystem takes the guesswork out of dental fabrication so faster workflows are just a few clicks away.

Product Demo: Form 3B Dental 3D Printer

In this webinar, Sam Wainwright, dental product manager at Formlabs, will walk through the new Formlabs Dental business unit and the Form 3B ecosystem, optimized to produce high quality dental parts and biocompatible appliances, including the step-by-step workflow for using the Form 3B.

The Easy Choice for Digital Appliance Production

Reclaim your time and produce parts you’ll be proud to deliver, without the hassle or prohibitive costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of dental experts.

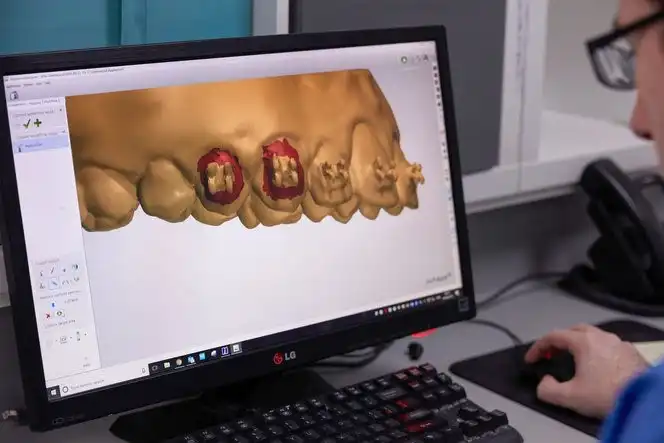

1. Scan

Collect patient anatomy digitally using an intraoral scanner. Send scans to the lab with a digital prescription or to a design station.

2. Design

Import scan data into CAD software, where the virtual design takes place.

3. Print

Import the designed CAD files into PreForm print preparation software for print setup and send them easily to a Formlabs printer.

4. Prepare

Wash, dry, and post-cure printed parts. These parts can then be used intraorally or be used to produce various indications.

The Next Generation of Dental 3D Printing

XY Resolution:

25 microns

Advanced Low Force Stereolithography (LFS)™ technology uses a flexible resin tank and a custom-designed, user-replaceable Light Processing Unit (LPU) to produce consistent, accurate prints. Reduced peel forces lead to incredible surface finish and part clarity, right off the printer.

Built for Production

Build Volume:

14.5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

Print 2-3 times more parts in a single build compared to small build plate DLP printers to spend less time handling your printer and more time on high-value tasks. Production environments can see 55% less labor time and costs compared to DLP. A modular ecosystem allows for unmatched consistency, scalability, and redundancy.

DENTAL DEMANDS MORE

Each of our ever-expanding variety of indications is extensively validated and tested to ensure quality and accuracy. Switch seamlessly between a library of Dental Resins with a no-hassle cartridge system.

Trusted by Dental Industry Leaders

With 75+ support and service staff and 150+ engineers, Formlabs backs its products with the strongest team in 3D printing.

| Printer Technology and Engine | |

|---|---|

| Print Technology | Laser-Powered Stereolithography (SLA) |

| Printer Engine | Low Force Stereolithography™ (LFS) |

| Key Components of the Print Engine | Laser Light Processing Unit (LPU) Flexible Film Resin Tank Intelligent Control Systems Automatic Resin Handling |

| Light Source | |

| Laser Type | 1 Light Processing Unit EN 60825-1:2014 certified Class 1 Laser Product 405 nm optical wavelength 250 mW laser 85 µm laser spot size |

| Print Speed and Tolerances | |

| Maximum Print Speed¹ | 31 mm/hour (1.2 in/hour) |

| Typical Print Speed² | Average: 11 mm/hour, Range: 4-17 mm/hour depending on material |

| Typical Dimensional Tolerances³ | Not measured |

| Surface Accuracy (Restorative Models)⁴ | Model Resin V3: 87% of surfaces within 100 µm, 66% within 50 µm Model Resin V2: 94% of surfaces within 100 µm, 73% within 50 µm |

| Materials | |

| Materials | 45 industry-leading materials, including 18 biocompatible materials or third-party materials via Open Platform |

| Biocompatible Materials | No (available on Form 4B) |

| Build Volume and Resolution | |

| Build Volume (W x D x H)⁵ | 14.5 × 14.5 × 19.3 cm (5.7 × 5.7 × 7.6 in), 4.05 liters |

| Build Area | 210 cm² (32.6 in²) |

| Maximum Part Length⁶ | 22.4 cm (8.8 in) |

| XY Resolution⁷ | 25 µm (0.001 in) |

| Layer Thickness⁸ | 25–300 µm (0.001–0.012 in) |

| Resin and Handling | |

| Resin Cartridges | 1 |

| Resin Cartridge Type | Original resin cartridge |

| Resin Heating | Air-heated print chamber |

| Internal Temperature | Auto-heats to 35 °C (95 °F) |

| Force Sensing | Z-Axis Force Sensor: optimizes print quality and speed based on part geometry and material |

| Supports | Auto-generated, light-touch removal |

| Dimensions and Environment | |

| Printer Dimensions (W x D x H) | 40.5 × 37.5 × 53 cm (15.9 × 14.8 × 20.9 in) |

| Minimum Access Dimensions (W x D x H) | 40.5 × 53 × 78 cm (15.9 × 20.9 × 30.7 in) |

| Printer Weight | 17.5 kg (38.5 lbs) |

| Operating Environment | 18–28 °C (64–82 °F) |

| Power and Connectivity | |

| Power Requirements | 100–240 VAC, 2.5 A, 50/60 Hz, 220 W |

| Connectivity | Wi-Fi (2.4 and 5 GHz), Ethernet (1000 Mbit), USB-B 2.0 |

| Printer Control⁹ | |

| Control Interface | 5.5″ interactive touchscreen, 1280 × 720 resolution |

| Supported Languages | English, Japanese, Traditional Chinese, Simplified Chinese |

| Alerts | |

| Alert Types | Touchscreen alerts, SMS/email via Dashboard, LED status indicators, audio alerts |

| Sensors and Control Systems | |

| Internal Sensors | – Convection resin heating with thermistor temperature sensing – Resin Level Sense – Z-Axis Force Sensor – Resin Cartridge Load Cell – Printer Leveling Sensor |

| Software | |

| Software | PreForm, Dashboard, Fleet Control |

| PreForm System Requirements | Windows 7 (64-bit) and up, Mac OS X 10.12 and up, OpenGL 2.1, 4 GB RAM (8 GB recommended) |

| PreForm File Types | STL, OBJ, 3MF input; FORM output |

| PreForm Print Setup Features | One-Click Print Adaptive layer thickness for faster printing with fine details Remote Print Auto-orient Auto-mesh repair Auto-generation of supports Manual support editing tools Rotate, scale, duplicate, mirror Layer slicer for path inspection Custom print settings Multi-language support |

| Dashboard Printer Management Features | |

| Dashboard Features | Manage prints and printers via the cloud Track resin and tank usage SMS/email alerts Enterprise group accounts with admin control |

| Resin and Light Processing Unit Estimated Lifetime | |

| Resin Tank Estimated Lifetime¹⁰ | 250-800 hours of printing or 10-35 weeks exposed to resin, depending on material |

| Light Processing Unit Estimated Lifetime¹¹ | Not measured |

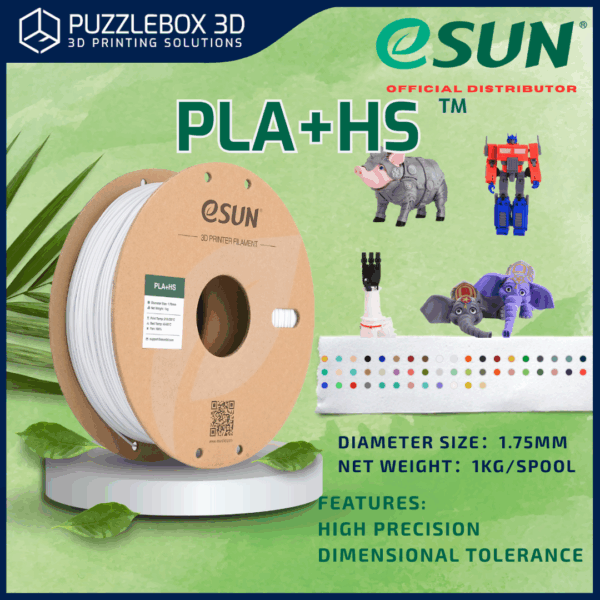

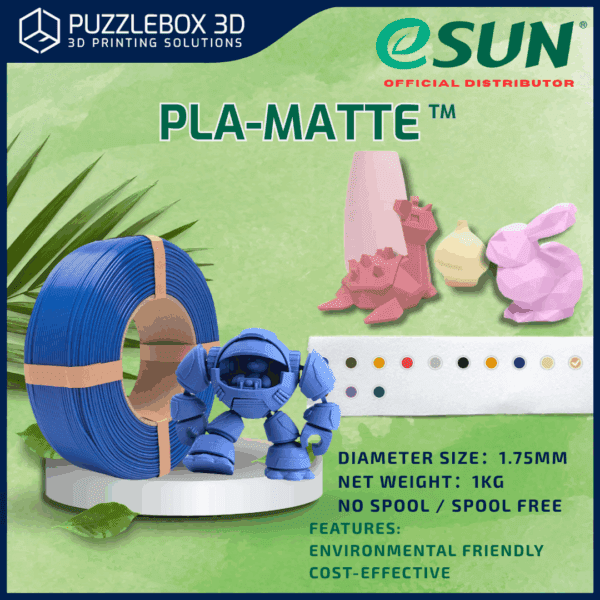

Filaments

eSun ABS-CF 3D Printing Filament 1.75mm Stronger, stiffer and more stable than regular ABS

₱1,399.00

Polymaker Panchroma PLA Dual Special 1kg3D Printing Filament Harmonious Contrast & Aesthetic Variety

₱999.00