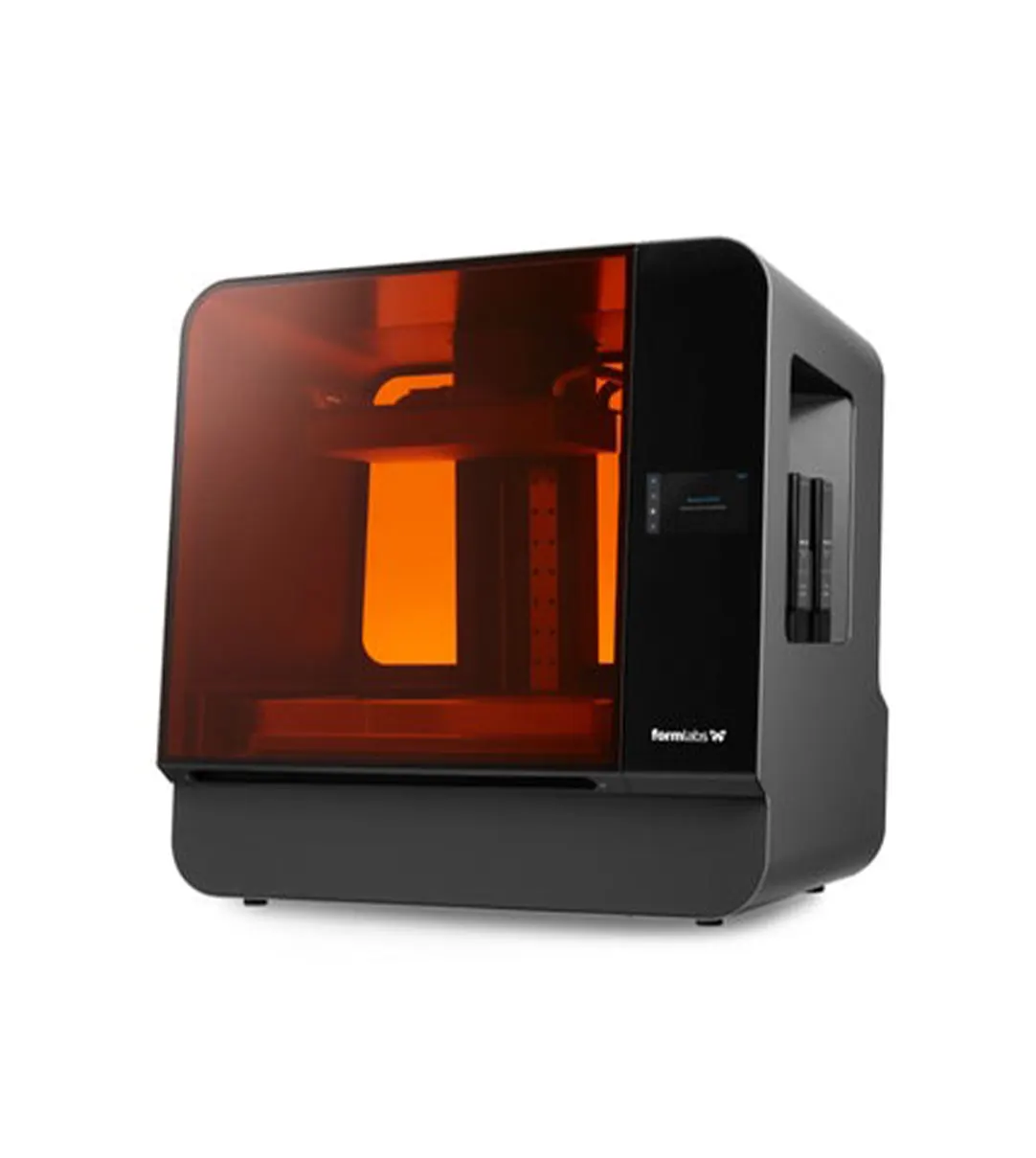

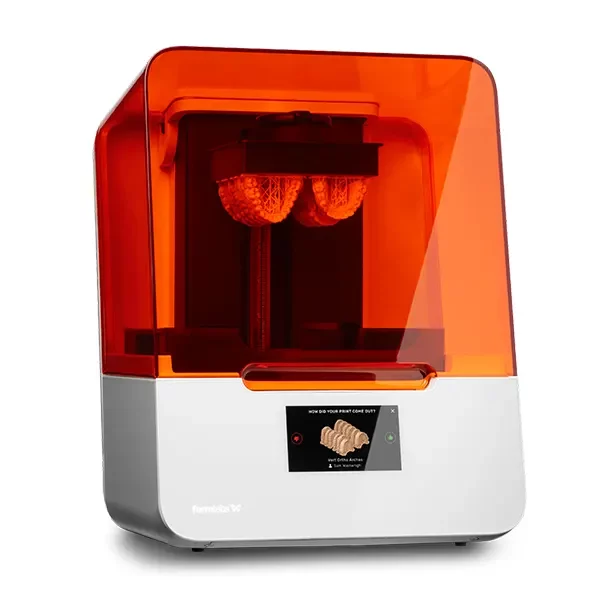

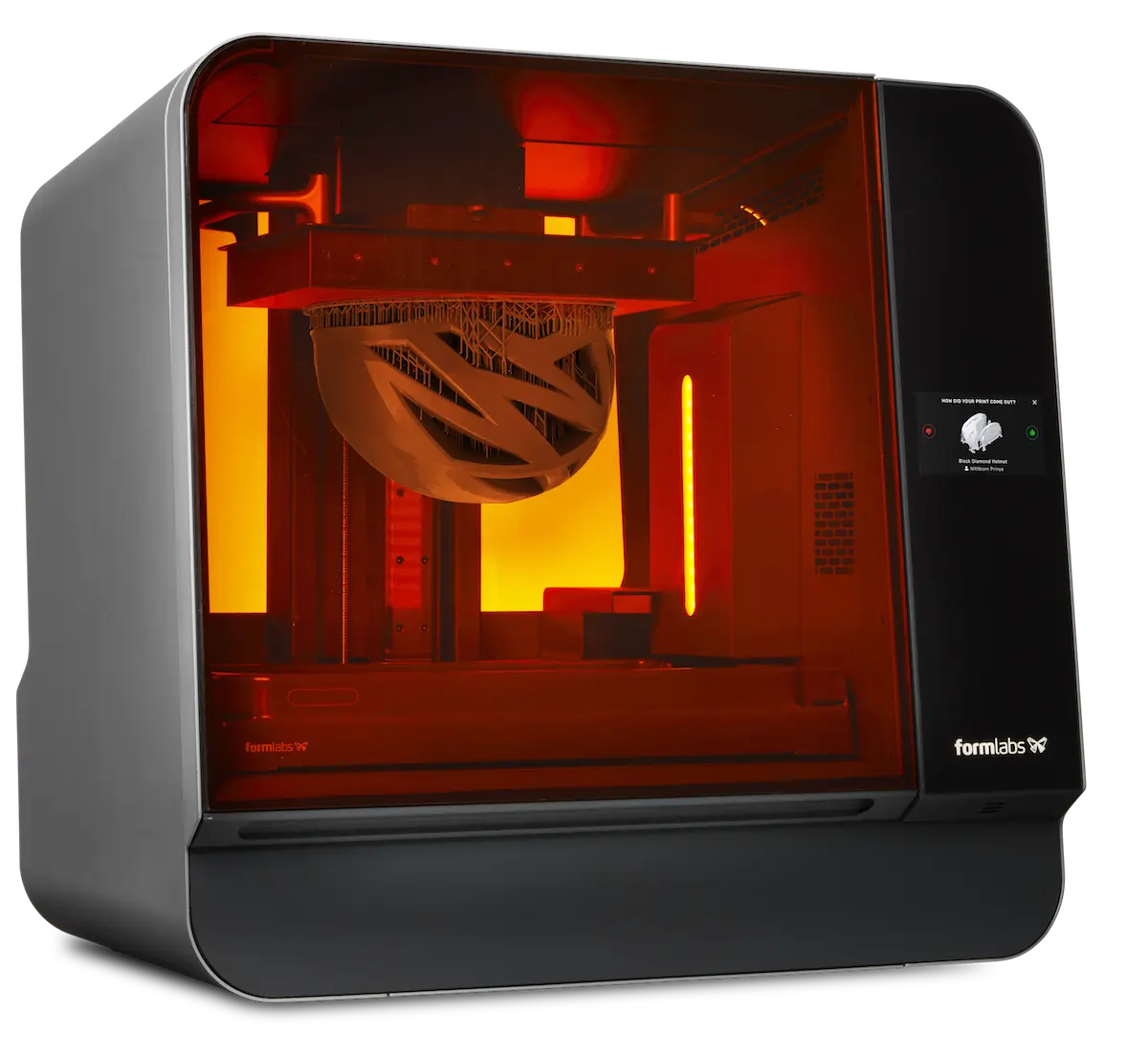

Formlabs Form 3L

Scale up your in-house print production with the Form 3L, an easy-to-use large format 3D printer for reliable production of industrial-quality parts.

Bring Large Format 3D Printing In-House

Scale up your in-house print production with the Form 3L, an easy-to-use large format 3D printer for reliable production of industrial-quality parts.

What's included in the Form 3L Package

Small Details, Big Results

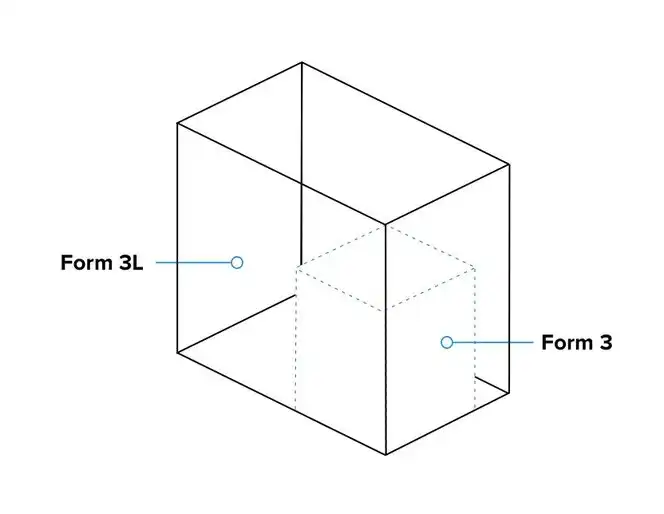

Eliminate the turnaround time of outsourcing or the manual work of assembly for large scale 3D prints. The Form 3L offers a massive build volume at an unprecedented value.

40,000,000 Parts Printed With Formlabs Technology

Incredible Part Quality

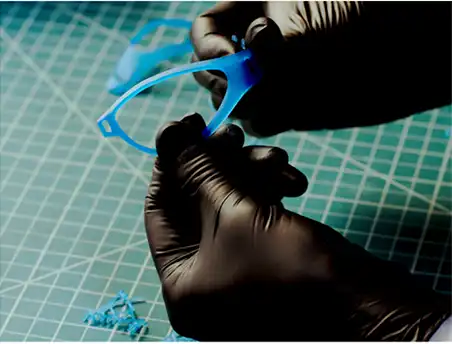

Stop sacrificing on quality for larger prints. The Form 3L provides the incredible surface finish and fine detail that stereolithography 3D printing is known for.

Optimized laser path:

Two staggered Light Processing Units (LPUs) inside the printer use a compact system of lenses and mirrors to deliver accurate, repeatable prints.

Crisp, clean features:

Each high-density laser passes through a spatial filter to guarantee a clean laser spot.

Consistent precision:

A parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform.

Intuitive and efficient

The Form 3L offers automatic resin dispensing, simple print preparation software, and an interface anyone at your company can use.

Nonstop printing:

Integrated sensors help maintain ideal print conditions and send you alerts about the state of your machine.

Closed-loop calibration:

Optical sensors continuously correct for scale and power, and can even detect dust.

User-replaceable components:

The Light-Processing Units, rollers and optics window can be replaced in-house, reducing the need for replacement print shipments.

| Printer Technology and Engine | |

|---|---|

| Print Technology | Laser-Powered Stereolithography (SLA) |

| Printer Engine | Low Force Stereolithography™ (LFS) |

| Key Components of the Print Engine | Laser Light Processing Unit (LPU) Flexible Film Resin Tank Intelligent Control Systems Automatic Resin Handling |

| Light Source | |

| Laser Type | 2 Light Processing Units EN 60825-1:2014 certified Class 1 Laser Product 405 nm optical wavelength Two 250 mW lasers 85 µm laser spot size |

| Build Volume and Resolution | |

| Build Volume (W x D x H)⁵ | 33.5 × 20 × 32 cm (13.2 × 7.9 × 12.6 in), 21.4 liters |

| Build Area | 670 cm² (104.3 in²) |

| XY Resolution⁷ | 25 µm (0.001 in) |

| Layer Thickness⁸ | 25–300 µm (0.001–0.012 in) |

| Materials | |

| Materials | 23 industry-leading Formlabs materials, or third-party materials via Open Platform |

| Biocompatible Materials | No (available on Form 3BL) |

| Resin and Handling | |

| Resin Cartridges | 2 |

| Resin Cartridge Type | Original resin cartridge |

| Resin Heating | Air-heated print chamber |

| Internal Temperature | Auto-heats to 35 °C (95 °F) |

| Force Sensing | Z-Axis Force Sensor: optimizes print quality and speed based on part geometry and material |

| Supports | Auto-generated, light-touch removal |

| Dimensions and Environment | |

| Printer Dimensions (W x D x H) | 77 × 52 × 74 cm (30.3 × 20.5 × 29.1 in) |

| Minimum Access Dimensions (W x D x H) | 90 × 96 × 104 cm (35.4 × 37.8 × 41 in) |

| Printer Weight | 54.4 kg (120 lb) |

| Operating Environment | 18–28 °C (64–82 °F) |

| Power and Connectivity | |

| Power Requirements | 100–240 VAC, 8.5A MAX, 50/60HZ, 650 W |

| Connectivity | Wi-Fi (2.4 and 5 GHz), Ethernet (1000 Mbit), USB-B 2.0 |

| Printer Control⁹ | |

| Control Interface | 5.5″ interactive touchscreen, 1280 × 720 resolution |

| Supported Languages | English |

| Alerts | |

| Alert Types | Touchscreen alerts, SMS/email via Dashboard, LED status indicators, audio alerts |

| Sensors and Control Systems | |

| Internal Sensors | – Convection resin heating with thermistor temperature sensing – Ultrasonic Resin Level Sense – Z-Axis Force Sensor – Resin Cartridge Load Cell – Printer Leveling Sensor |

| Software | |

| Software | PreForm, Dashboard, Fleet Control |

| PreForm System Requirements | Windows 7 (64-bit) and up, Mac OS X 10.12 and up, OpenGL 2.1, 4 GB RAM (8 GB recommended) |

| PreForm File Types | STL, OBJ, 3MF input; FORM output |

| PreForm Print Setup Features | One-Click Print Adaptive layer thickness for faster printing with fine details Remote Print Auto-orient Auto-mesh repair Auto-generation of supports Manual support editing tools Rotate, scale, duplicate, mirror Layer slicer for path inspection Custom print settings Multi-language support |

| Dashboard Printer Management Features | |

| Dashboard Features | Manage prints and printers via the cloud Track resin and tank usage SMS/email alerts Enterprise group accounts with admin control |

| Resin and Light Processing Unit Estimated Lifetime | |

| Resin Tank Estimated Lifetime¹⁰ | 250-800 hours of printing or 10-35 weeks exposed to resin, depending on material |

| Light Processing Unit Estimated Lifetime¹¹ | Not measured |

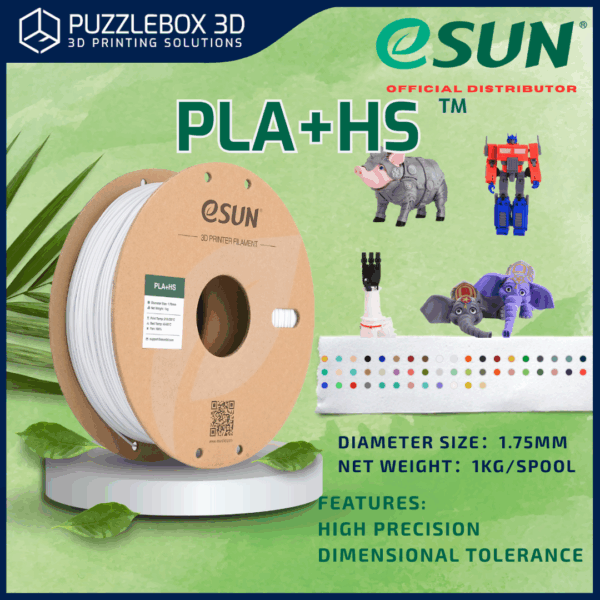

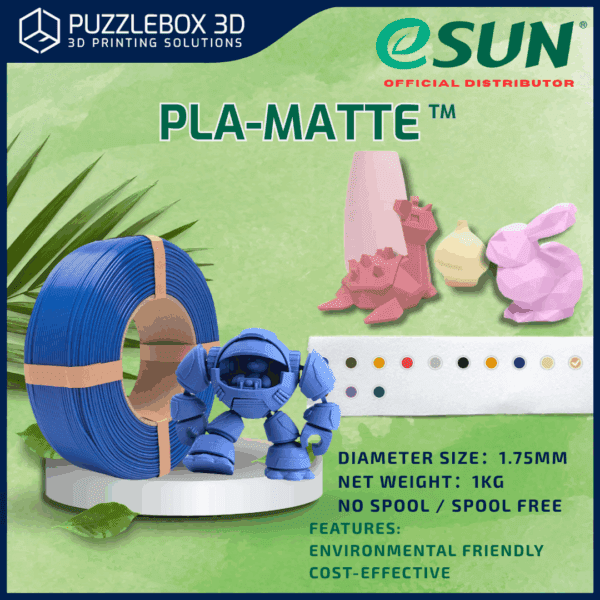

Filaments

eSun ABS-CF 3D Printing Filament 1.75mm Stronger, stiffer and more stable than regular ABS

₱1,399.00

Polymaker Panchroma PLA Dual Special 1kg3D Printing Filament Harmonious Contrast & Aesthetic Variety

₱999.00