Magigoo – Drywise Dryer

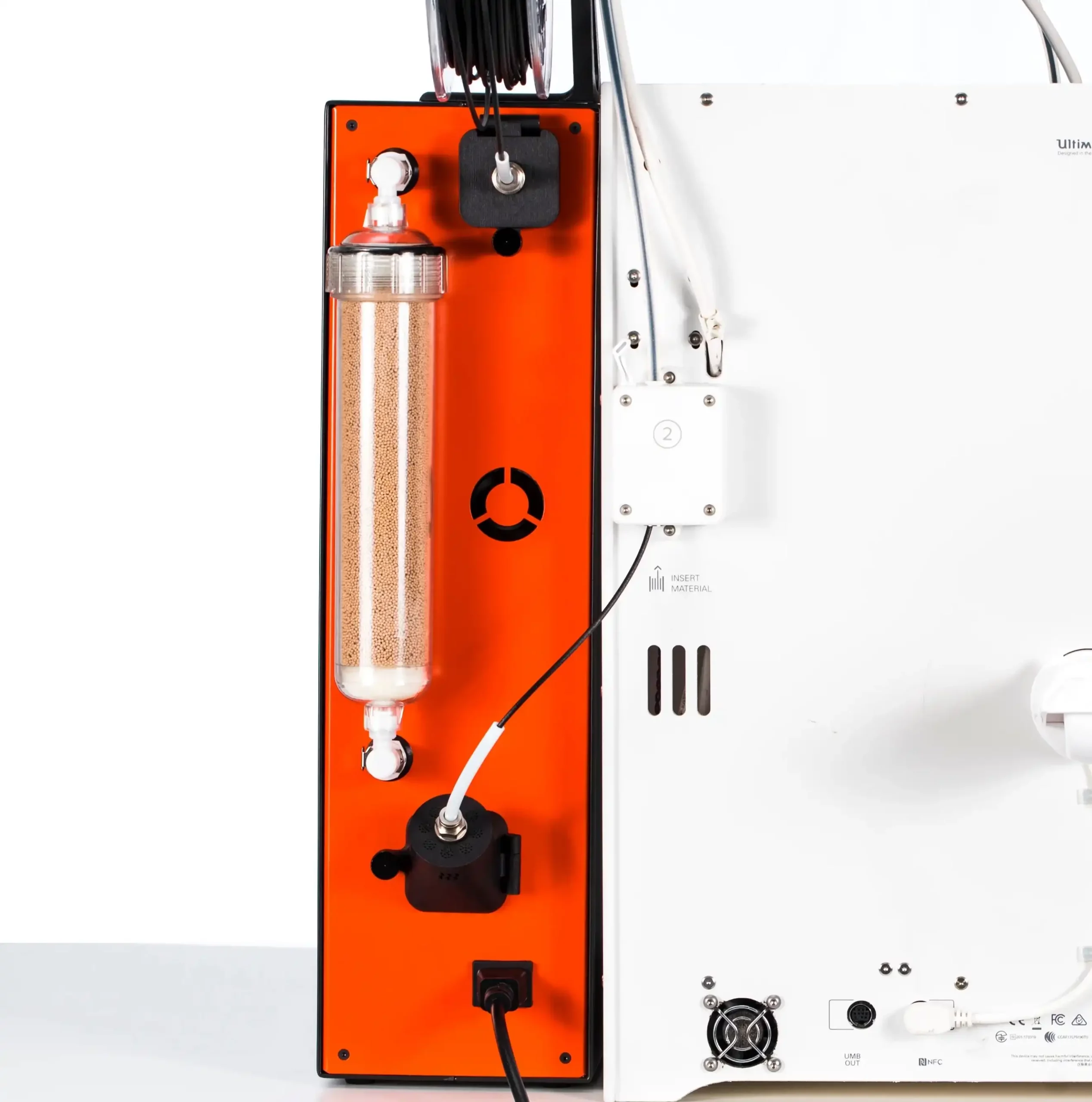

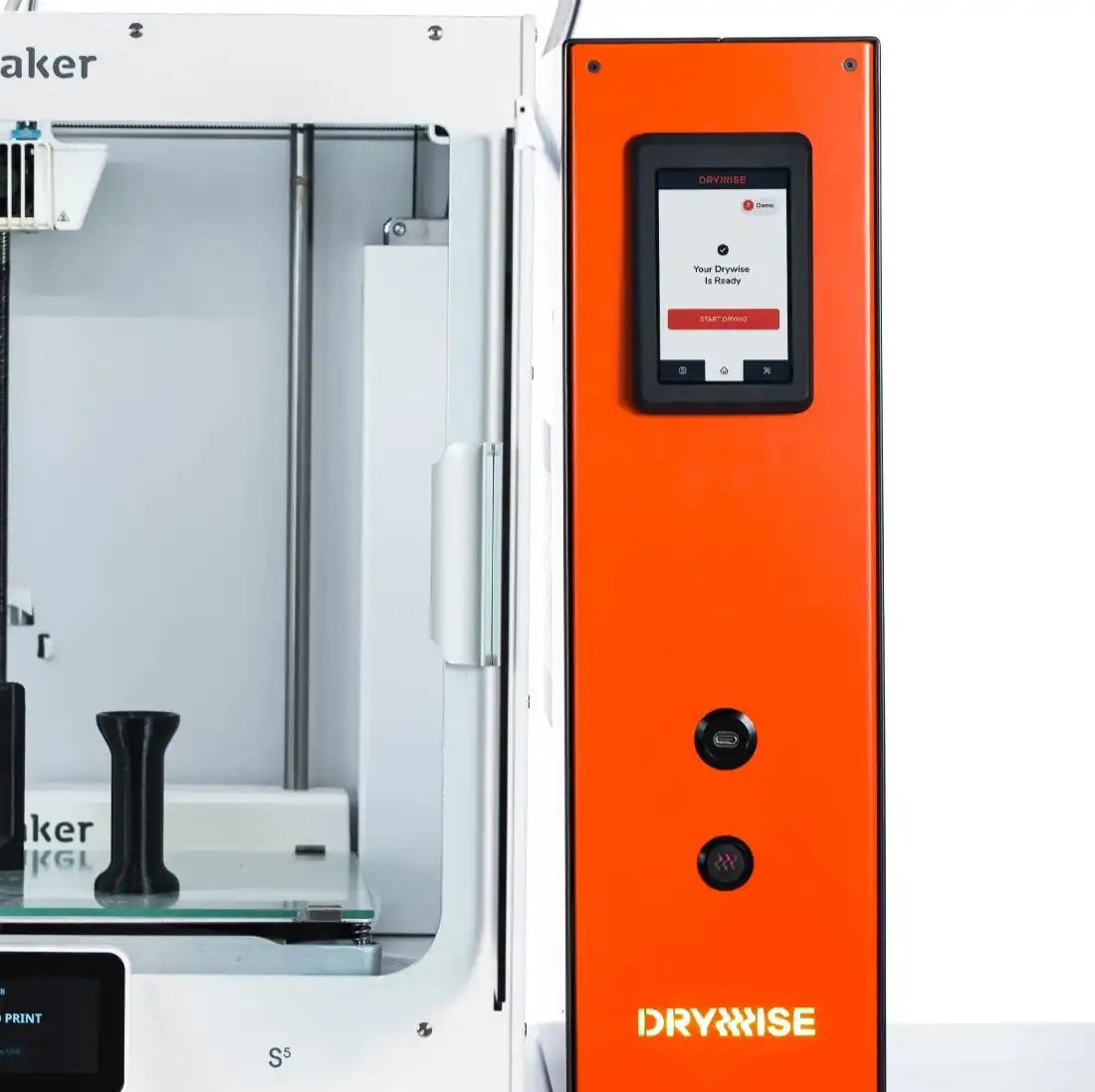

The Drywise filament dryer takes out the guesswork when 3D printing hygroscopic materials. The Drywise needs about 50 minutes to pre-treat your filament and bring it to the best printing conditions before 3D printing can start. An in-line drying design assures that long 3D prints will always be printed with consistent material dried to best printing conditions.

Magigoo – Drywise Dryer

The Drywise filament dryer takes out the guesswork when 3D printing hygroscopic materials. The Drywise needs about 50 minutes to pre-treat your filament and bring it to the best printing conditions before 3D printing can start. An in-line drying design assures that long 3D prints will always be printed with consistent material dried to best printing conditions.

Ultimate Material Quality Control

Significant Time Savings

Valuable time is gained thanks to the quasi instant drying, a feature of the in-line drying architecture. Further, the pre-calibrated settings for certified materials eliminate guesswork and remove the need to research settings.