Polymaker PolyLite PLA 3KG 3D Printing Filaments

PolyLite PLA 3KG is a family of 3D printing filaments made with the best raw materials to deliver exceptional quality and reliability. PolyLite™ covers the most popular 3D printing materials to meet your everyday needs in design and prototyping.

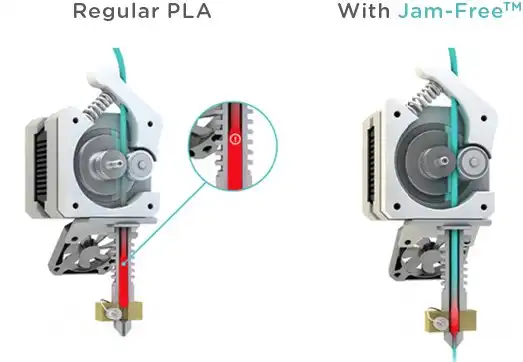

PolyLite™ PLA features Jam-Free™ technology and is formulated for high-quality reliability and ease of printing.

Jam-Free™ technology improves the heat stability of Polymaker’s PLA filaments with softening temperatures over 140 °C. As a result, Polymaker’s PLA filaments show minimal softening in the “cold end” and can melt rapidly once entering the heating zone, leading to excellent printing quality with zero risk of nozzle jams.

₱2,449.00

Polymaker PolyLite PLA 3KG 3D Printing Filaments

PolyLite PLA 3KG is a family of 3D printing filaments made with the best raw materials to deliver exceptional quality and reliability. PolyLite™ covers the most popular 3D printing materials to meet your everyday needs in design and prototyping.

PolyLite™ PLA features Jam-Free™ technology and is formulated for high-quality reliability and ease of printing.

Jam-Free™ technology improves the heat stability of Polymaker’s PLA filaments with softening temperatures over 140 °C. As a result, Polymaker’s PLA filaments show minimal softening in the “cold end” and can melt rapidly once entering the heating zone, leading to excellent printing quality with zero risk of nozzle jams.

₱2,449.00

Polymaker Polylite™ Filament

PolyLite™ is a family of 3D printing filaments made with the best raw materials to deliver exceptional quality and reliability. PolyLite™ covers the most popular 3D printing materials to meet your everyday needs in design and prototyping.

PolyLite™ PLA is a high-quality PLA designed for reliability and ease of printing.

PolyLite™ PLA features Jam-Free™ technology:

Jam-Free™ technology improves the heat stability of Polymaker’s PLA filaments with softening temperatures over 140 °C. As a result, Polymaker’s PLA filaments show minimal softening in the “cold end” and can melt rapidly once entering the heating zone, leading to excellent printing quality with zero risk of nozzle jams.

Printing Properties:

- Nozzle Temperature:

190˚C – 230˚C - Printing Speed:

40mm/s – 60mm/s - Bed Temperature:

25˚C – 60˚C - Bed Surface:

Glass with glue, Blue Tape, BuilTak® - Cooling Fan:

ON

Printing conditions may vary with different printers and nozzle diameters

Mechanical Properties:

- Young’s Modulus:

2636 ± 330 Mpa - Tensile Strength:

46.6 ± 0.9 Mpa - Bending Strength:

85.1 ± 2.9 Mpa - Charpy Impact Strength:

2.7 ± 0.2 kJ/m2

Thermal Properties:

- Glass Transition Temperature:

61˚C - Vicat Softening Temperature:

63˚C - Melting Temperature:

150˚C

Notes:

- Drying Settings:

80˚C for 8h - Recommended Support Materials:

PolyDissolve™ S1, PolySupport™ - Other:

N/A

TDS:

SDS:

PIS:

PRINT SETTINGS

Nozzle Temperature:

190˚C – 230˚C

Printing Speed:

40mm/s – 60mm/s

Bed Temperature:

25˚C – 60˚C

Bed Surface:

Glass with glue, Blue Tape, BuilTak®

Cooling Fan:

ON

Based on 0.4 mm nozzle and Simplify 3D v.3.1. Printing conditions may vary with different printers and nozzle diameters

MECHANICAL PROPERTIES

Young’s Modulus:

2636 ± 330 Mpa

Tensile Strength:

46.6 ± 0.9 Mpa

Bending Strength:

85.1 ± 2.9 Mpa

Charpy Impact Strength:

2.7 ± 0.2 kJ/m2

THERMAL PROPERTIES

Glass Transition Temperature:

61˚C

Vicat Softening Temperature:

63˚C

Melting Temperature:

150˚C

NOTES

Drying Settings:

80˚C for 8h

Recommended Support Materials:

PolyDissolve™ S1, PolySupport™