Polymaker PolyWood 600g

PolyWood™ is a wood mimic filament without actual wood powder, which removes all risks of nozzle clogs. PolyWood™ is made entirely with PLA using a special foaming technology. It exhibits the same density and appearance as wood.

₱1,649.00

Polymaker PolyWood™ Filament

This Specialty family provides unique filaments from Polymaker to unlock new 3D printing applications.

PolyWood™ is a wood mimic filament without actual wood powder, which removes all risks of nozzle clogs. PolyWood™ is made entirely with PLA using a special foaming technology. It exhibits the same density and appearance as wood.

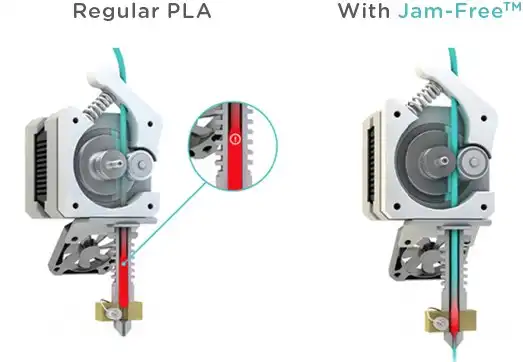

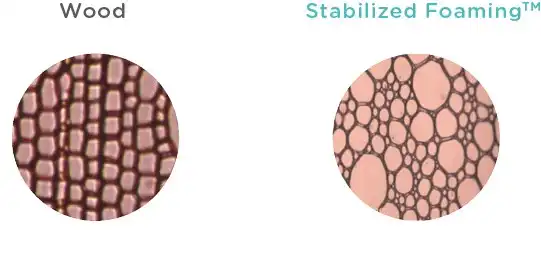

PolyWood™ features Polymaker's Jam-Free™ technology and Polymaker's Stabilized Foaming™ technology:

Jam-Free™ technology improves the heat stability of Polymaker’s PLA filaments with softening temperatures over 140 °C. As a result, Polymaker’s PLA filaments show minimal softening in the “cold end” and can melt rapidly once entering the heating zone, leading to excellent printing quality with zero risk of nozzle jams.

Stabilized Foaming™ technology is used to produce foamed filaments, whose foam structure can survive the printing process and be inherited by the printed parts. This enables light weight 3D printed parts with unprecedented surface finish.

Printing Properties:

- Nozzle Temperature:

190˚C – 210˚C - Printing Speed:

35mm/s – 50mm/s - Bed Temperature:

25˚C – 60˚C - Bed Surface:

Glass with glue, blue tape, BuilTak® - Cooling Fan:

ON

Printing conditions may vary with different printers and nozzle diameters

Mechanical Properties:

- Young’s Modulus:

N/A - Tensile Strength:

23.2 ± 0.4 Mpa - Bending Strength:

52.9 ± 0.3 Mpa - Charpy Impact Strength:

2.1 ± 0.2 kJ/m2

Thermal Properties:

- Glass Transition Temperature:

62˚C - Vicat Softening Temperature:

60˚C - Melting Temperature:

151˚C

Notes:

- Drying Settings:

70˚C for 8h - Recommended Support Materials:

PolyDissolve™ S1

Other:

N/A

TDS:

DOWNLOAD

SDS:

DOWNLOAD

PIS:

DOWNLOAD