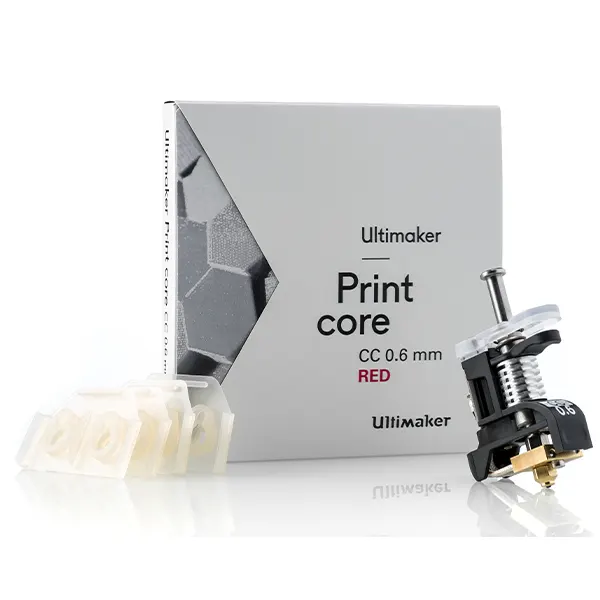

Ultimaker CC Print Core 0.6

The print core CC 0.6, 0.4 and CC red 0.6 are specially designed to print with composite materials on the Ultimaker S5 and Ultimaker S3. Here you can find all information on how to use the print core.

CC 0.6 and 0.4 print cores

The print core CC 0.6, 0.4 and CC red 0.6 are specially designed to print with composite materials on the Ultimaker S5 and Ultimaker S3. Here you can find all information on how to use the print core.

Using the CC print cores

Using the CC print cores is similar to using any of the other print cores on the Ultimaker S5 and Ultimaker S3. The print core can be changed, loaded, or unloaded via the configuration menu on the printer as described in the Ultimaker S5 manual and Ultimaker S3 manual.

The CC 0.4 print core has full compatibility with Ultimaker Cura 4.10 onwards and with S-line firmware 6.5 on the latest channel or 6.2.2 on the stable channel.

Ultimaker is proud to announce the Ultimaker print core CC – the newest addition to our line of print cores suited to specific job types and applications, from manufacturing to prototyping. It acts as both an update and replacement for the print core CC Red, offering increased robustness, reliability, and much more. We can’t wait to see what you do with it.

Welcome to the ecosystem

With a wear-resistant, hardened steel nozzle and available in multiple nozzle sizes, the Ultimaker print core CC unlocks the power to print high-strength applications with extra stiffness and rigidity, using a wide range of composite materials from the Ultimaker ecosystem.

The Ultimaker print core CC joins the Ultimaker ecosystem to stand alongside the Ultimaker print core AA and the Ultimaker print core BB. Each print core is designed to serve a purpose – giving you the freedom to design, create, and print, assured that you have the right tools for the job.

Here’s a rundown of its key features:

Multiple print cores, maximum flexibility

Two nozzle sizes – 0.4 mm, enabling you to print detailed parts, tools, or prototypes with higher visual quality, and 0.6 mm, for shorter print times and improved efficiency – will result in easier optimization of composite applications.

The Ultimaker print core CC 0.4's smaller nozzle size means your prints will feature higher levels of detail, thinner line widths, and a smooth surface finish – enabling you to print parts or prototypes with the visual quality you need.

And by using the Ultimaker print core CC 0.6 to print with bigger line widths, your composite applications will be ready as quickly as possible – saving you time in a busy, hardworking environment that requires efficiency and speed.

The new Ultimaker print core CC 0.4 features a 0.4 mm nozzle size.

This is ideal for printing fine detail on parts, such as text to differentiate tools.

Reliable, robust, ready for work

The Ultimaker print core CC features an all-new design with an abrasion-resistant, hardened steel nozzle and titanium heat break. Reliable, robust, and compatible with a wide range of composite 3D printing materials, you'll unlock the power to print high-strength applications that are ready for work.

Ultimaker print cores are designed to enable configuration changes in a matter of seconds.

Quick swap – no tools necessary

With a quick-swap design, the Ultimaker print core CC – like all Ultimaker print cores – can be quickly and easily changed, tool-free, to meet the requirements of any print job, increasing your efficiency and decreasing downtime.

Plus, the print core's EEPROM chip memorizes the size and type of your nozzle, meaning fewer printing errors and an increased chance of success.

Built for market-leading composites

The Ultimaker print core CC is ideal for printing with the wide range of composite materials available in the Ultimaker Marketplace. Here's what some of the leading material brands say about the print core...

"The Ultimaker print core CC has been a workhorse for us here at Jabil. Our PA 4035 CF filament, which is a PA 12 with 35% carbon fiber by weight, is quite abrasive, so having a highly wear resistant nozzle is a must. We were excited to learn about the 0.4 mm offering, which gives us the flexibility to print finer feature detail than the 0.6 mm nozzle, while maintaining the same reliability and durability we’ve come to appreciate." – Levi Loesch, Process Engineer at Jabil Additive Manufacturing

“The CC 0.4mm print core is very well constructed and provides the next level of accuracy when using composite materials. It allows to print smaller features with a greater level of details when compare with the 0.6mm one. In addition, the surface finishing of our CF reinforced materials get even better than before!” – Thiago Medeiros Araujo, LEHVOSS Group

"The high accuracy in printing carbon fiber or glass fiber filled parts with the print core CC 0.4mm is as good as unfilled printed parts and we did not need to adjust speed or other parameters. We printed with our Ensinger TECAFIL PA6 GF30 and there were no blobs, clogging effects or any other issue that influences the printing process or the quality of the part. Overall the print core CC works very well and as it should." – Marius Graf, AM Development Engineer at Ensinger GmbH

Compatibility

The CC print cores are intended for use on the Ultimaker S5 and Ultimaker S3 only. Although the Ultimaker 3 uses AA and BB print cores, we strongly advise against the use of the print core CC Red 0.6 on this printer.

The reason for this is that the feeder of the Ultimaker 3 is not optimized for working with composite materials. When using composite materials on the Ultimaker 3 – even when a CC print core is installed – the ‘teeth’ of the knurled wheel inside the feeder will erode and cause unreliable material flow and under-extrusion. In the Ultimaker S5 and Ultimaker S3 feeder the knurled wheel is made from a stronger material, which means that it won’t wear when using composite materials.

Please be aware that continuing and using the CC print cores with the Ultimaker 3 is at your own risk and not officially supported by Ultimaker.

Caution: The CC 0.6 and 0.4 print cores can be used at a maximum temperature of 300°C. Although models can be sliced at higher temperatures, the print jobs will not be accepted on the printer.

Supported materials

Since the CC print cores are specifically designed for use with composite materials, it is not supported with any of Ultimaker’s own materials. Ultimaker materials are non-abrasive and can therefore be used with the standard AA or BB print cores. Composite materials of third-party material suppliers can however wear out the nozzle of the AA and BB print cores. For this reason, they should be printed with the print core CC Red.

Because of the open filament system on the Ultimaker S5 and our collaboration with several leading material companies, profiles for various third-party composite materials are provided via the Ultimaker Marketplace.