Countries have been gathering at the COP26 climate change summit in Glasgow to agree how to slow the global rise in temperatures. 45% of global greenhouse gas emissions come from the ways that we produce and consume our products and food.¹ The way we make and use things needs to change – but what part can 3D printing play?

Introducing the circular economy

According to the charity, The Ellen MacArthur Foundation, the circular economy is a model in which “our throwaway economy [is transformed] into one where waste is eliminated, resources are circulated, and nature is regenerated”.

It’s based on the concepts of nature that have sustained life for billions of years. There is no waste. Instead, waste becomes food, energy comes from the sun, and organisms break down into the soil at their end of their lives. Human societies operate very differently, wasting resources and degrading the ecosystems we all rely on for life.

https://www.youtube.com/watch?v=zCRKvDyyHmI

Efficient small-batch production

Around 40% of all plastic products are thrown away within one month.² While plastics are the basis of many essential products, it’s important to ask the question, do we need it all? And so much of it?

Part of the problem is that plastic products and parts are typically produced in large volumes via injection molding, to make the production cost effective. Once the mold is ready, the manufacturer is committed to making hundreds of thousands of copies of it to justify the investment. If the design of the product turns out to be flawed or unpopular, that creates a lot of waste.

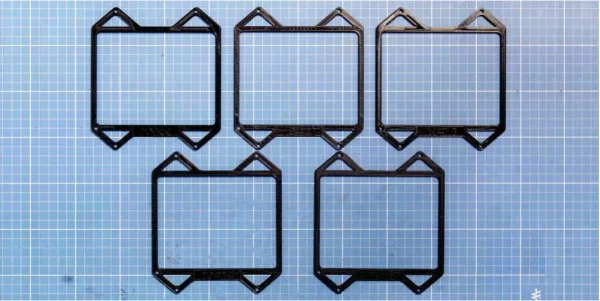

A batch of adapter plates for ZEISS microscopes, printed on an Ultimaker 3D printer

Reducing transport and packaging

The global transport sector accounts for about one-fifth of global carbon dioxide emissions.³ And almost 40% of plastic is used for packaging,² which primarily exists to protect items during transport.

If you have access to a 3D printer, creating a new part or prototype doesn’t have to mean a delivery.

Of course, 3D printing material still needs to be produced and shipped. But from one bulk order you can print many parts, cutting out steps in the supply chain that would have otherwise meant trucks on the road or planes in the sky.

Extending product life with replacement parts

Who hasn’t experienced that guilty feeling when throwing something away when only one component is broken?

Perhaps the most valuable contribution 3D printing can make to a circular economy is the potential of 3D printed parts to extend the life of other products.

An original part from a packaging machine (right) and the 3D printed replacement (left), which also includes design improvements

Recycling materials

You may have been thinking up this point, this is all great, but don’t 3D printers use plastic filament? That’s correct. Even with the benefits outlined above, you still need to consider the impact of the material you are using.

But there are things you can do to reduce this impact, or even make the 3D printing filament itself part of a circular economy.

As a start, we recommend checking out some of the 3D printing materials out there made from recycled plastic. There are several available in the Ultimaker Marketplace.

Ian Falconer of Fishy Filaments turns old fishing nets into 3D printing materials

References: