3D Printing provides a significant boost for businesses in almost all types of industries in the market. There are plenty of applications where 3D printers can be useful, for example, in manufacturing and engineering where it can be used for rapid prototyping and on-demand production of tools, jigs, fixtures and even machine spare parts. In education where it can be used for learning, research and even housed inside a Fablab. Healthcare and dental, jewelry, architecture, aerospace, businesses and many more. Used in these industries, 3D printers help by reducing cost and lessen the lead time which leads to a significant increase in productivity of the business.

Driven by technology and passionate about innovation, Ultimaker offers a world class, easy to use, and reliable 3D Printer which anyone can use. With the development of the S-Line 3D Printers, this is much upgraded, more accessible, with smart features. Businesses are now able to transform their 3D Printing workflow in higher productivity which can deliver more accurate and functional output.

Allow us to elaborate to you more of why you should choose to get one of these S-Line 3D Printers and discover its value to your business.

Ultimaker S-Line 3D Printers: S3, S5 and S5 Pro Bundle

1. Simple set up, easy to use with smart features – It can provide high-quality results after a 30-minute introduction. Its award-winning touch interface, quick-swap print cores, and predefined print settings enable rapid changeovers and reduce operator time needed.

Touchscreen Interface

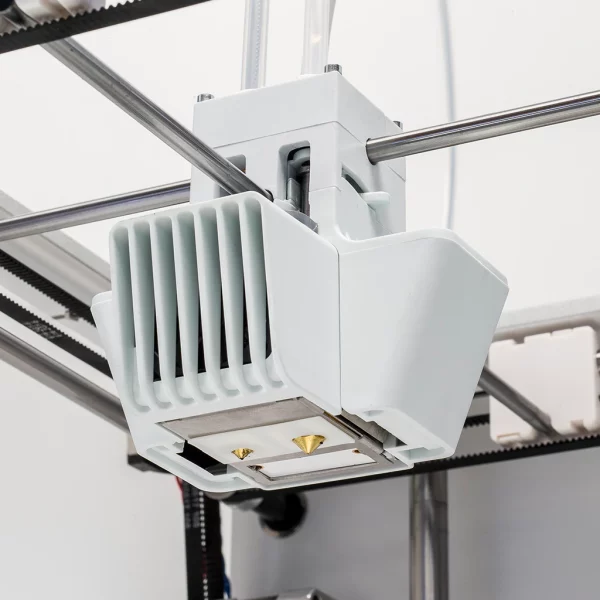

2. Reliable Dual Extrusion – The advanced active leveling of these printers, stiffer build platform, heated build plate, and more accurate stepper drivers produces the highest print quality of a machine in this form factor. A dual filament flow sensor notify you if you run out of material.

Dual Extruder print head

3. Accessibility – It can produce parts or models you need using any filament, from any desktop, as part of any workflow, and quickly achieve ROI.

Material Selection

4. Delivers accurate, composite-ready prints – With Ultimaker’s pioneering alliance with global materials companies, S-Line 3D Printers offers an easy way to print with the world’s most advanced filaments – including glass and carbon fiber composites.

For non-abrasive filaments, switch between build and support material in seconds, choosing from 0.8, 0.4, or 0.25 mm print cores for fast or detailed prints. To unlock more high-end applications with abrasive materials, select print core CC Red 0.6 which is sold separately.

Ultimaker sample prints

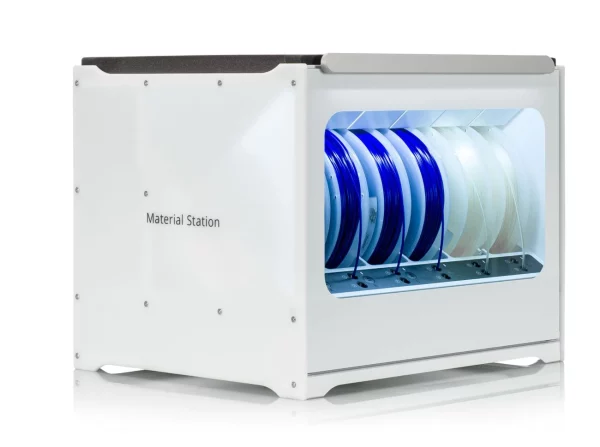

5. Unlocks 24/7 connectivity – With Ultimaker Material Station which unlocks 24/7 production and maintains the quality of materials by keeping the polymer from degrading overtime and removes the risk of moisture absorption. It loads up to six material spools inside the humidity controlled chamber with smart features such as composite-ready feeder wheels, filament flow sensors, and automatic switching when a material runs out. This will help you can achieve increased productivity and higher-quality production.

Ultimaker Material Station

6. Ensures safer work environment – Ultimaker Air Manager prevents people from touching hot or moving parts during a print. It filters up to 95% of all ultrafine particles (UFPs) emitted during 3D printing and forms a safe, physical barrier to the print area. It maintains a more stable print environment inside the printer which allows people to print even more materials than before.

Ultimaker Air Manager

Now that you already have these 6 reasons in mind, this will help you decide what 3D Printer suits to your needs.

Good luck to your 3D Printing journey!