Flashforge Guider 3 Ultra 3D Printer Philippines

Ultra high speed 3D printing at a commercial and industrial grade levels is what the FlashForge Guider 3 Ultra can offer to your business. Featuring CoreXY design for extreme high throughput while maintaining the legendary Flashforge reliability and quality.

Flashforge Guider 3 Ultra 3D Printer Philippines

Ultra high speed 3D printing at a commercial and industrial grade levels is what the FlashForge Guider 3 Ultra can offer to your business. Featuring CoreXY design for extreme high throughput while maintaining the legendary Flashforge reliability and quality.

With the new ultra-fast algorithm and lightweight and stable structural design,

Guider 3 Ultra enhances its active vibration compensation performance, features

continuous and stable high-speed operation, and realizes rapid integral forming

of complex models, truly leading high-efficiency manufacturing.

Up to 2000g/day

24/7 Continuous and

stable printing

Easy to use:

Tool-free, 3s quick-release nozzle, One-click printing, fully auto-leveling

500mm/s (printing speed)

20000mm/s² (acceleration)

Dual extruder design for building complex models

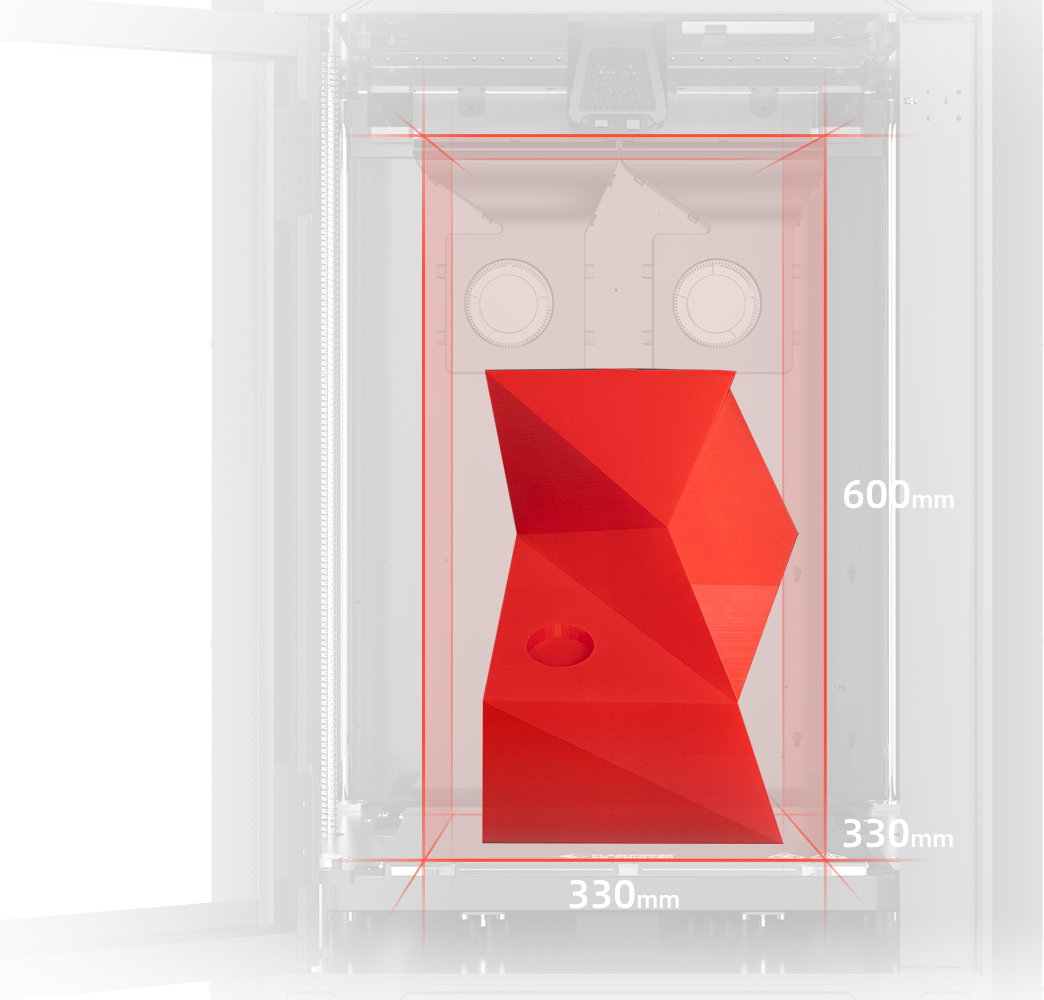

Ultra-large build volume

Max. volume: 330*330*600mm

Made for High-Speed and Highly-Efficient Production

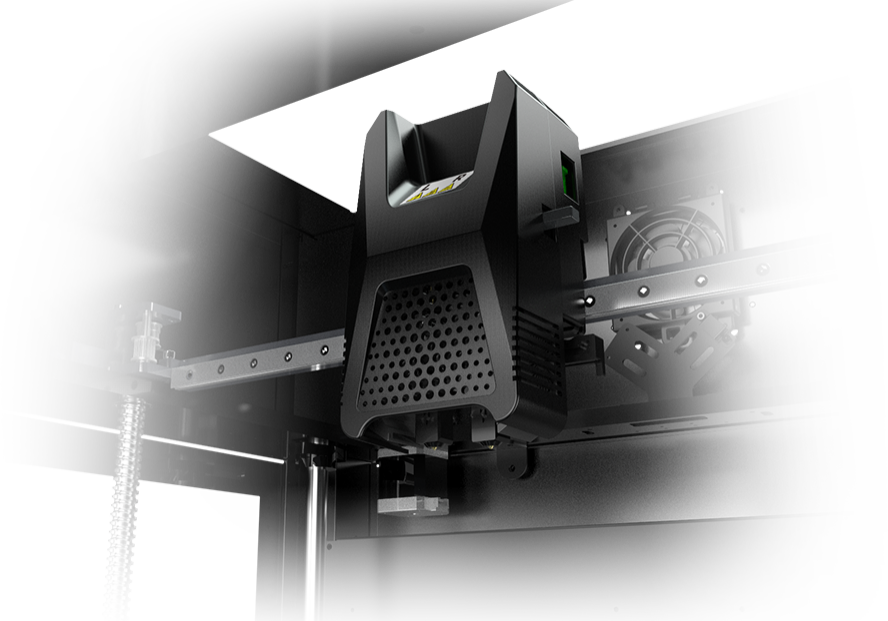

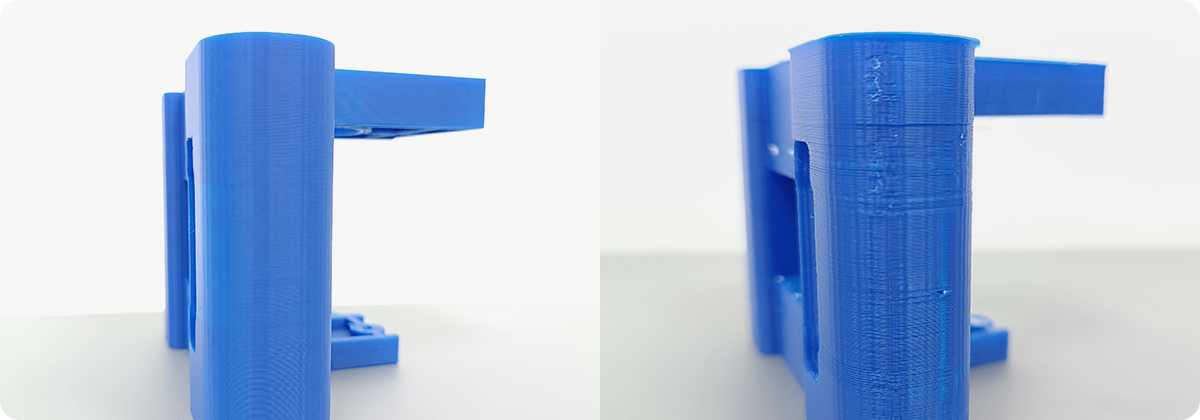

Stable High-Speed Printing,

Eliminating Ghosting & Ringing

- Lighter extruder and beam design to reduce the inertia when running at high speed;

- With our exclusive self-developed extruder vibration suppression algorithm, vibrations occurred during high-speed printing can be automatically compensated, thus reduce ringing in prints.

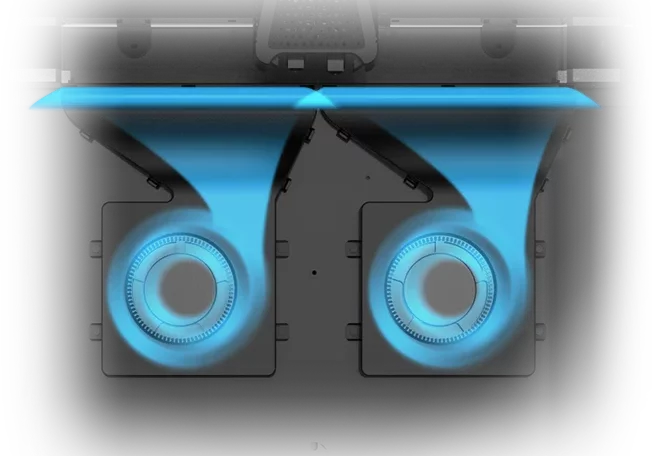

Air Cooling System

The powerful dual-fan air-blowing cooling system can quickly cool down the filament extruded by the nozzle, and ensure that each layer of filament is fully cooled in the high-speed printing mode, offering higher molding accuracy.

Large-size models can be printed for delivery in one day. Approximately 90% of regular-size models can be printed within 24 hours.

Industrial Part

300×125×400mm | 15% infill

20 hrs 39 min

Fixture

305×105×100mm | 70% infill

13 hrs 44 min

Maximum productivity up to 2000g/day

Dual Extruder Design for Building Complex Models

- Support printing easy-to-remove and soluble support materials;

- Suitable for printing complex models with overhangs, bridges and hollow structures

Full auto-leveling, real one-click printing

Dual-extruder Switching Testing

100,000 times

High-strength

TBI ball screws

Continuous Use

10,000 hours

Stable Load-bearing

Platform

Continuous and Stable Printing

24/7

Large Size, Expanding Boundaries

Meet the needs of printing models of various sizes;

The maximum model height can be up to 600mm.

Tool-Free,

3s Quick-Release Nozzle

Save maintenance time without affecting the whole printing process.

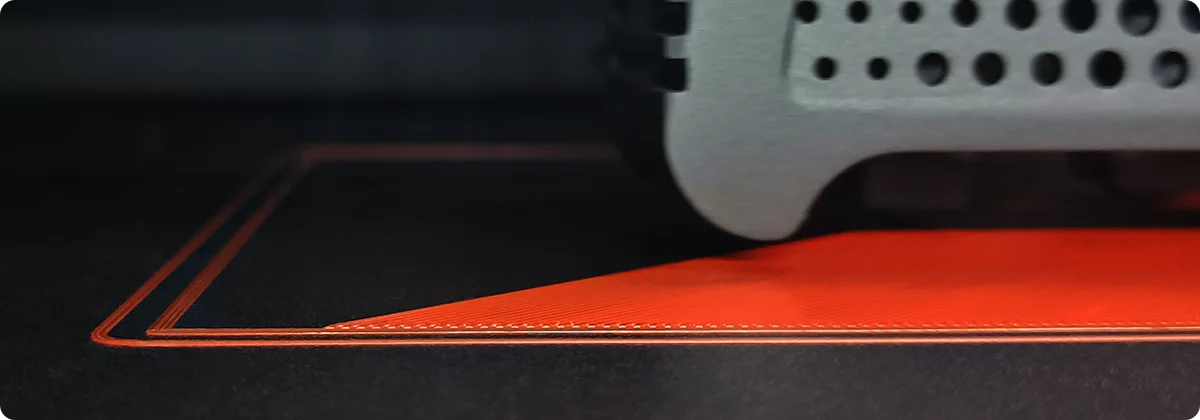

Excellent Surface Quality

Equipment of outstanding performance, slicing software using intelligent path planning algorithm, and own-brand filaments developed under continuous innovation

- Each layer is accurately positioned, with smooth and delicate finish.

- The extruder pressure compensation algorithm realizes accurate control of the amount of filament that is extruded in advance, resulting in smooth printing and flawless first layer.

- The exclusive vibration suppression algorithm automatically compensates the vibrations during high-speed printing, thus eliminating ringing.

With the vibration suppression algorithm vs. Without the vibration suppression algorithm

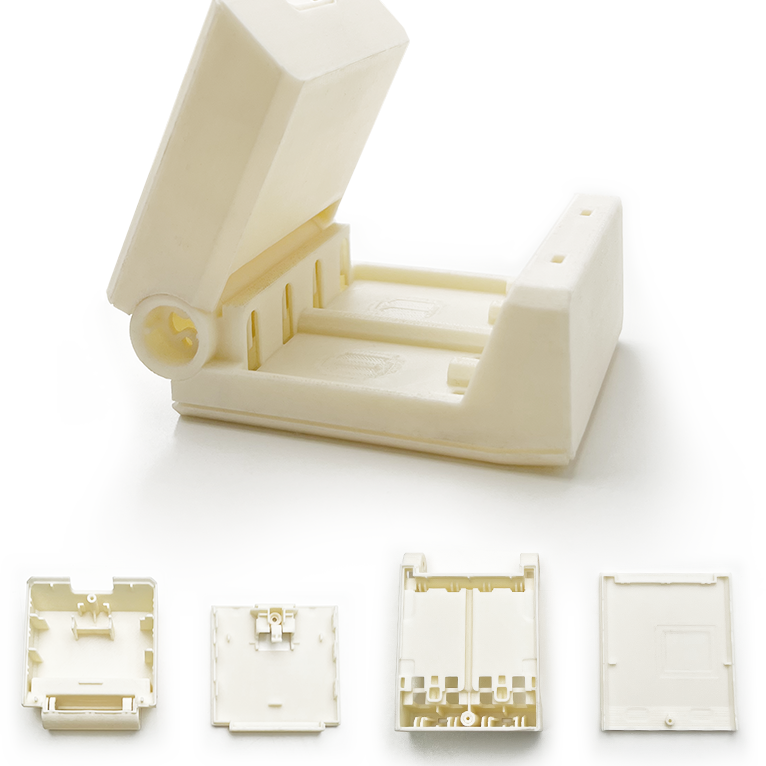

±0.15mm

tolerance;

precise assembly of complex kits

Name: Battery box assembly

Material: ABS

Application: Dimensional verification and functional testing of multiple kits in the design and R&D phase

Printed curved surface:

Fine and Smooth

Name: Impeller

Material: PETG-CF

Application: Design verification of appearance and functions

Built-in HD Camera

Remote Real-time Monitoring

Filament Detector Filament

Run-out Reminder

Automatically detect filament shortage

and pause printing. Printing can be

resumed after filament fed

Power Loss Recovery

Avoid failed prints due to accidental power

outages and guarantee normal printing

HEPA 13 Air Filtration System

Filter dust, particles and odors, ensuring

an environmentally-friendly and safe

working environment

Auto Shutdown

Models can be printed at night safely and ready

for pick-up during the day.

Sealed Filament Drying Chamber

Support a wide range of general and engineering filaments

- Extruder temperature up to 350℃

- PLA/ABS/HIPS/PC/TPE/PETG/ASA/

PP/Nylon/Glass fiber reinforced/

Carbon fiber reinforced filament

* Note: Glass fiber reinforced and carbon fiber reinforced filaments should be used with high-strength nozzles.

Compatible with third-party filaments

Open third-party material configuration:

The software synchronously configures multi-brand

material data, which is convenient for customers to

choose suitable filament by themselves.

| Basic Parameters | |

|---|---|

| Extruder Quantity | 2 |

| Printing Precision | ±0.15 mm or ±0.002mm/mm (The larger value shall prevail) |

| Positioning Accuracy | X/Y-axis 0.011 mm; Z-axis 0.0025 mm |

| Printing Speed | Max. 500mm/s |

| Printing Acceleration | 20000mm/s² |

| Layer Thickness | 0.05 ~ 0.4 mm |

| Build Volume | Single Extruder: 330 x 330 x 600 mm Dual Extruder: 300 x 330 x 600 mm |

| Nozzle Type | High-strength nozzle |

| Nozzle Diameter | 0.4 (Default), Optional (0.6 / 0.8mm) |

| Maximum Extruder Temperature | 350 ℃ |

| Maximum Platform Temperature | 120 ℃ |

| Printing Bed | Flexible steel plate |

| Supported Filament | PLA / PETG / ASA / ABS / PC / PA / PLA-CF / PETG-CF / PETG-GF / PA-CF / PA-GF |

| Dimensions | |

| Device Size | 635(L) × 550(W) × 1070(H)mm |

| Packaging Size | 775(L) × 690(W) × 1235(H)mm |

| Software | |

| Slicing Software | FlashPrint |

| Compatible Operating System | Windows XP / Vista / 7 / 8 / 10 / Mac OS |

| Input File Format | 3MF / STL / OBJ / FPP / BMP / PNG / JPG / JPEG |

| Output File Format | GX / G / gcode |

| Compatible Slicing Software | Slic3r / Cura (Needs setup) |

| Power Supply | |

| Input | AC100-240V |

| Output | 50-60Hz, 850W MAX |

| Other Functions | |

| Printing Connection | U Disk / Ethernet / Wi-Fi |

| Smart LCD Touch Screen | 7-inch |

| Thermostatic Circulation System | × |

| Quick-release Extruder | ✔ |

| Fully-enclosed Design | ✔ |

| Automatic Leveling | ✔ |

| Filament Run-out Reminder | ✔ |

| Replaceable Build Plate | ✔ |

| Ultra-silent Design | ✔ |

| Power Loss Recovery | ✔ |

| Remote Video Monitoring | ✔ |

| Wi-Fi | ✔ |

| Ethernet Port | ✔ |

| USB Port | ✔ |

| Air Filter Net | ✔ |

| Cloud Platform | ✔ |

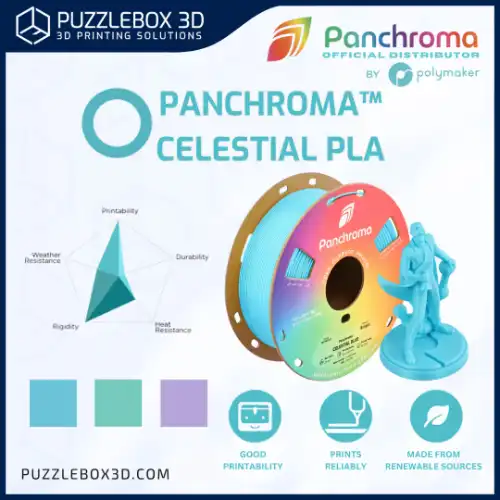

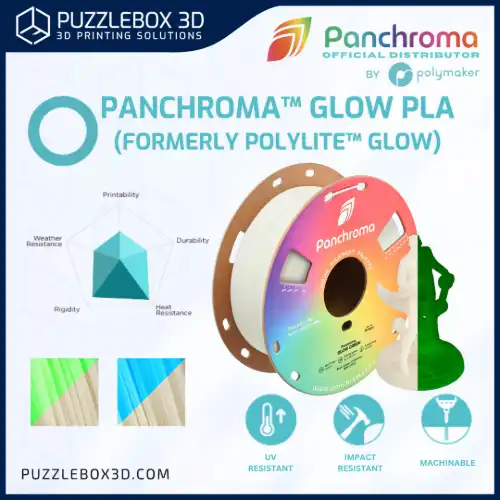

Filaments