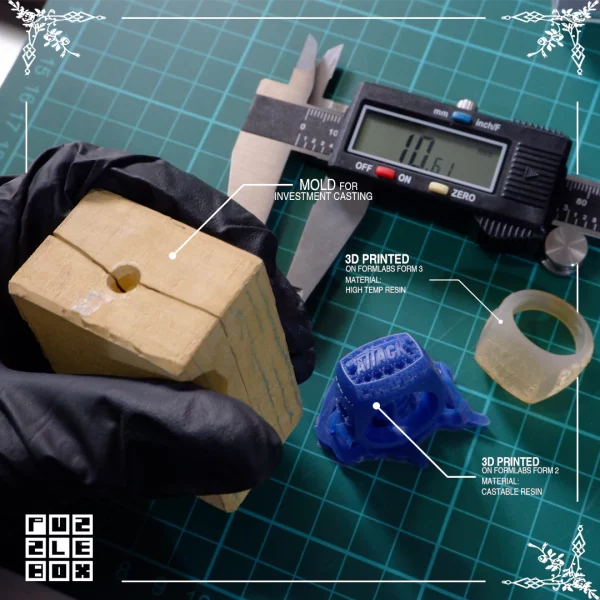

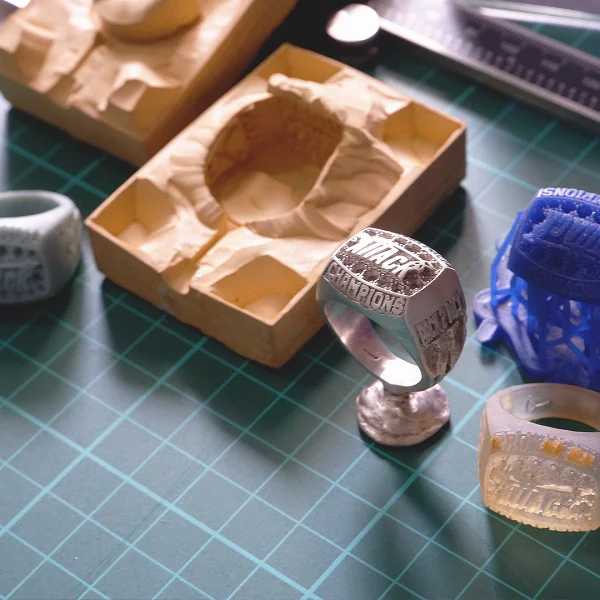

Castable Resin

Our Original Formulation for Direct Investment Casting

Our original formulation for direct investment casting. This pure polymer requires an alternate burnout from a typical wax schedule.

High Temp Resin

For Vulcanized Rubber Molding

High Temp Resin is strong enough to withstand the temperatures and pressures of medium temperature vulcanized rubber molding. Download our white paper to learn how to use Formlabs High Temp and Standard Resins for vulcanized rubber molding and room temperature vulcanization (RTV) processes.

Castable Wax Resin for Sharp Detail and Clean Casting Every Time

A 20% wax-filled material for reliable casting with zero ash content and clean burnout, Castable Wax Resin accurately captures intricate features and offers the smooth surfaces stereolithography 3D printing is known for. Printed parts are strong enough to handle with no post-cure required, suitable for custom try-ons and direct investment casting.