Polymaker PolyCast 750g

Polymaker PolyCast 750g

₱2,749.00

PolyCast™ is a filament designed to produce investment patterns for investment casting applications. 3D printing significantly cuts down both the cost and lead time by eliminating the tooling process.

Brand:

Same Day Shipping

Polymaker PolyCast™ Filament

This Specialty family provides unique filaments from Polymaker to unlock new 3D printing applications.

PolyCast™ is a filament designed to produce investment patterns for investment casting applications. 3D printing significantly cuts down both the cost and lead time by eliminating the tooling process.

PolyCast™ features Polymaker’s Layer-Free™ technology and Polymaker’s Ash-Free™ technology

Layer-Free™

Layer-Free™ technology involves exposing a 3D printed part to an aerosol of micro-sized alcohol droplets, generated by a rapidly vibrating, perforated membrane called the nebulizer. The aerosol will then be adsorbed by the surface of the 3D printed part and render it smooth and layer-free.

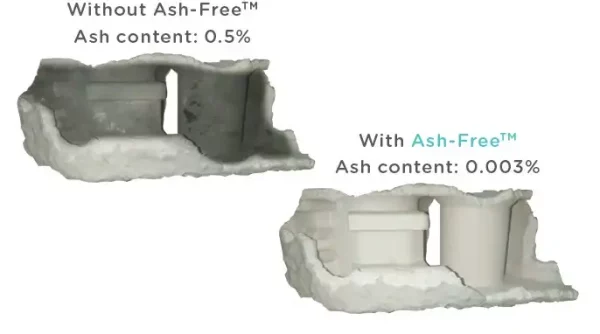

Ash-Free™

Ash-Free™ technology allows Polymaker’s filament which has been designed for investment casting to burn off cleanly without any residue, enabling defect-free metal parts. 3D printing has been used to produce investment casting patterns as it cuts down both the cost and lead time for small-volume production runs.

Printing Properties

- Nozzle Temperature:

190˚C – 220˚C - Printing Speed:

40mm/s – 60mm/s - Bed Temperature:

25˚C – 70˚C - Bed Surface:

Glass with glue, blue tape - Cooling Fan:

ON

Printing conditions may vary with different printers and nozzle diameters

Mechanical Properties:

- Young’s Modulus:

1745 ± 151 Mpa - Tensile Strength:

37.5 ± 1.7 Mpa - Bending Strength:

60.2 ± 1.6 Mpa - Charpy Impact Strength:

9.6 ± 0.9 kJ/m2

Notes:

- Drying Settings:

60˚C for 12h - Recommended Support Materials:

PolyDissolve™ S1

Other:

It is highly recommended to use the PolyBox™ when printing with PolyCast™ and to store it in the resealable bag.

Application Note:

DOWNLOAD

TDS:

DOWNLOAD

SDS:

DOWNLOAD

PIS:

DOWNLOAD